How long for electrolysis to eat through copper pipe?

anniel89

18 years ago

Featured Answer

Sort by:Oldest

Comments (17)

baymee

18 years agokudzu9

18 years agoRelated Professionals

Franklin Plumbers · Chantilly Handyman · Fullerton Kitchen & Bathroom Remodelers · Broadlands Kitchen & Bathroom Remodelers · Champlin Kitchen & Bathroom Remodelers · Chandler Kitchen & Bathroom Remodelers · Idaho Falls Kitchen & Bathroom Remodelers · Park Ridge Kitchen & Bathroom Remodelers · Rolling Hills Estates Kitchen & Bathroom Remodelers · Sicklerville Kitchen & Bathroom Remodelers · Skokie Kitchen & Bathroom Remodelers · Spokane Kitchen & Bathroom Remodelers · Turlock Kitchen & Bathroom Remodelers · Wilson Kitchen & Bathroom Remodelers · Hewitt Kitchen & Bath Fixturesbaymee

18 years agopinocchio

18 years agobrickeyee

18 years agolazypup

18 years agoUser

18 years agobrickeyee

18 years agooutdoors_2006

17 years agobrickeyee

17 years agoshacko

17 years agolazypup

17 years agoshacko

17 years agotbenton

16 years agolazypup

16 years agobrickeyee

16 years ago

Related Stories

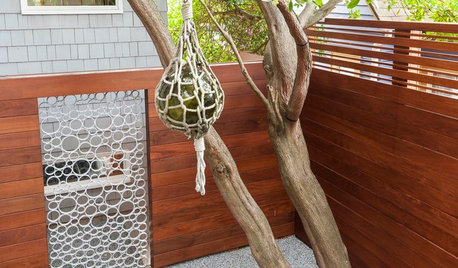

FENCES AND GATESA Designer Uses PVC Pipe to Cast a Modern Garden Gate

Landscape designer Scot Eckley walks us through the process of creating a custom aluminum ring gate

Full Story

REMODELING GUIDES15 Ways to Design With Copper

Get Inspired to Add the Long-Lasting Beauty of Copper to Your Home

Full Story

KITCHEN DESIGNKitchen of the Week: A Burst Pipe Spurs a Makeover

Once dark and clunky, this compact kitchen in a 1962 ranch is now light, bright and cheerful

Full Story

LIFEThe Polite House: How Can I Tell a Construction Crew to Pipe Down?

If workers around your home are doing things that bother you, there’s a diplomatic way to approach them

Full Story

ARCHITECTURECylinders — More Than Architects’ Pipe Dreams

They may look fanciful, but cylinders can serve practical purposes in architectural designs

Full Story

INSIDE HOUZZHow Much Does a Remodel Cost, and How Long Does It Take?

The 2016 Houzz & Home survey asked 120,000 Houzzers about their renovation projects. Here’s what they said

Full Story

KITCHEN DESIGN16 Scrumptious Eat-In Kitchens and What They Want You to Serve

Whether apple-pie cheerful or champagne sophisticated, these eat-in kitchens offer ideas to salivate over

Full Story

KITCHEN DESIGNKitchen of the Week: Double Trouble and a Happy Ending

Burst pipes result in back-to-back kitchen renovations. The second time around, this interior designer gets her kitchen just right

Full Story

BATHROOM DESIGNRoom of the Day: A Salvaged Bathroom Full of Fresh Ideas

Entwined pipes as faucets, old doorknobs as towel hooks and swaths of concrete bring function and attitude to a master bath

Full Story

RUSTIC STYLEA Quirky Country Kitchen With a Story to Tell

Creative thinking goes a long way in this kitchen packed with love for family and old treasures

Full Story

User