Plumbint Ox Box with PEX

Bruce in Northern Virginia

9 years ago

More Discussions

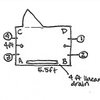

I bought the washing machine Ox Box from Home Depot and the supply side connectors on the bottom are 1/2" pipe. I bought Sharkbite female NPT to PEX adapters, screwed them on the Ox Box (using teflon tape on the threads) and crimped the PEX on to the adapter. But now the adapter is leaking where its threaded on to the Ox Box. It is not leaking at the PEX crimp fitting.

The Ox box is plastic, so I didn't want to get carried away when I screwed on the adapters; however, I was able to use an allen wrench to hold the valve (there was a fitting for it), and a crescent wrench to tighten the adapter very snugly. Did I use the right adapter (NPT) for the threaded fitting on the Ox Box, or should I be using some other type of adapter for these threaded fittings?

I have the same type of threaded fittings on a Delta universal shower valve, so I want to make sure I'm using the right adapters to connect the PEX.

Thanks,

Bruce

bus_driver

Bruce in Northern VirginiaOriginal Author

Related Professionals

Fairfax Handyman · Avondale Kitchen & Bathroom Remodelers · Broadlands Kitchen & Bathroom Remodelers · Centerville Kitchen & Bathroom Remodelers · Clovis Kitchen & Bathroom Remodelers · Elk Grove Village Kitchen & Bathroom Remodelers · Lyons Kitchen & Bathroom Remodelers · Manassas Kitchen & Bathroom Remodelers · New Port Richey East Kitchen & Bathroom Remodelers · Port Arthur Kitchen & Bathroom Remodelers · Rancho Palos Verdes Kitchen & Bathroom Remodelers · Rolling Hills Estates Kitchen & Bathroom Remodelers · Phillipsburg Kitchen & Bathroom Remodelers · Gibsonton Kitchen & Bathroom Remodelers · Tanque Verde Kitchen & Bath Fixturesbus_driver

Bruce in Northern VirginiaOriginal Author

bus_driver

Bruce in Northern VirginiaOriginal Author

bus_driver

Bruce in Northern VirginiaOriginal Author