Water Softener

I am hoping someone can help me find a Water Softener that will meet my needs. To provide you with details:

Hardness - 336mg/l (approx 20GPG)

Iron - None found

The plumbing coming into the house is 1" and current flow rate it approx 10GPM.

There are 4 people in the house and we have 2 full bathrooms and one half bathroom.

There is no current plumbing for a Water Softener so I will be running the lines. I am planning on running 1.25" lines to the Water Softener from the 1" line running into the house in an effort to not restrict the flow any further.

I would like to find a non-electric Water Softener if possible, but am open to other options if they provide better features/functionality. I would like to get a Fleck system, but am confused between the 5600, 5000, 7000, and 2510. The 5600 has been around the longest from what I have read, but am concerned about the 3/4 internal piping restricting the flow too much. Having never had a Water Softener, I am really not sure though if that will be an issue.

Thanks in advance for any information you provide.

Comments (38)

Related Professionals

Boise Plumbers · Minnetonka Mills Kitchen & Bathroom Remodelers · Channahon Kitchen & Bathroom Remodelers · Elk Grove Kitchen & Bathroom Remodelers · Las Vegas Kitchen & Bathroom Remodelers · Niles Kitchen & Bathroom Remodelers · North Arlington Kitchen & Bathroom Remodelers · Patterson Kitchen & Bathroom Remodelers · Pueblo Kitchen & Bathroom Remodelers · Rancho Palos Verdes Kitchen & Bathroom Remodelers · Saint Helens Kitchen & Bathroom Remodelers · South Lake Tahoe Kitchen & Bathroom Remodelers · South Plainfield Kitchen & Bathroom Remodelers · Phillipsburg Kitchen & Bathroom Remodelers · Tanque Verde Kitchen & Bath Fixturesjcalhoun

10 years agoUnless there is an issue with making soap lather you could probably get away without one.

If you do decide you can't live without it, define what you really need it to do and get something that does that very well and skip the rest. You don't need to treat water that has already been treated.

dgarmanJAX

Original Author10 years agoWater, even city water, is not treated for hardness - thus the need for a softener. And yes, the water is very hard and needs to be softened. Thanks

grandmum

10 years ago"JCalhoun-

Unless there is an issue with making soap lather you could probably get away without one. "Please elaborate as 20gph hardness is very high, almost as high as my water. I too would like to "get away with one" .

dgarmanJAX

Original Author10 years agoI work for an environmental testing laboratory, so had the water tested for Hardness and Metals. Hardness is 336ppm. As for TDS, according to the city's website it is 686ppm. I could not find a pH anywhere in the report, so doesn't look like they tested it and I didn't test it either, so don't know what it is.

The link to the water report is here - http://viewer.zmags.com/publication/65d27263#/65d27263/6.

Also, I'm seeing that there aren't many non-electric systems, so am open to whatever will work. I've been looking at the Fleck 5600 Econominder and SXT models and can't really tell what the difference is beside the SXT being a digital display and configuration.

Really wanting to understand why I'm going to get what I'm going to get, not just that I need "X" - so please provide as much detail regarding any recommendation so I can understand better.

Thanks again for time to respond.

jcalhoun

10 years agoThe rule of thumb is that if your water will make soapy suds and lather then the water is not all that hard. If you can't make good lather then the water is overly hard.

dgarmanJAX

Original Author10 years agoI have crystals on my shower head from the hardness. My dishwasher does not clean the dishes very well. How much something suds or lathers is an objective opinion and really isn't valid in determining whether a softener is needed or not.

Additionally I didn't ask if you think I need a softener. I asked for help in finding a softener. If you don't think I need one that's fine, but I didn't ask for anyone's opinion as to whether I need one or not. I know I need one, just need help finding the right one.

Thanks

User

10 years agoOh, for pity's sake, jcalhoun. Analysis trumps a soap-suds test. As someone who claims to work in some sort of water treatment industry, you ought to know this. Do you control your water treatment facility based on guesses or analysis? Soap suds, or lack thereof, is only one aspect of potential hardness issues. The OP has already expressed interest in a softener.

dgarmanJAX - Your water report does not include iron, but since you've indicated no iron and your TDS is low, softener sizing is relatively easy.

I understand you wish to know why I am making the recommendation I am making, but I'm a bit pressed for time at the moment, so I'll provide the recommendation with as much info as I have time for at present. Hopefully that will suffice. If not, please don't hesitate to ask further questions and I will answer them as soon as i am able.

If you want a non-electric model, you will need to go with Kinetico. They are entirely different from the typical Fleck softener, smaller in size, packed bed, smaller resin, more susceptible to damage from particulates, more expensive, but highly reliable.

A 2.0 cubic ft softener will do nicely, if you go with a Fleck. Get the 7000sxt to avoid the size constraints of the 5600 model, and cost difference is minimal. Do not get the Ecominder - it regenerates based on time rather than water usage which ends up wasting water and salt. Also, there is no need to increase the pipe size to 1.25" for the softener lines - the pressure drop through that small length of pipe will not be noticeable.

Here are some things to look for so you can start making comparisons among local and online (if you are willing to accept total responsibility for your system) vendors.

High quality American or German made resin. This will provide a tight size distribution for optimal flow within the resin

Since you have CITY WATER: 10% crosslinked resin. The oxidizers that city water treatment plants use, such as chlorine or chloramine, are harmful to softener resins. Higher crosslinking will resist chemical attack longer.

Top basket. This serves two purposes. It sets up a proper water distribution during normal operation and prevents resin loss during backwash.

Gravel underbed. The gravel underbed is there to set up proper flow patterns, improve backwash and prevent channeling. Many softener sales companies like to leave this out or sell softeners with a vortex system instead. Vortex systems weigh less than gravel so they cost less to ship. In addition, they are a more expensive item that adds profit for the softener salesperson, but provides no additional benefit to the homeowner . It simply adds another piece of equipment that can break.

Fleck or Clack valves. These set the industry standard. Be aware that you will not be able to purchase Clack valves online. This is not a problem if you purchase locally.

Noryl bypass. Most softeners are available with either Noryl or stainless...

User

10 years ago"If you want a non-electric model, you will need to go with Kinetico. They are entirely different from the typical Fleck softener, smaller in size, packed bed, smaller resin, more susceptible to damage from particulates, more expensive, but highly reliable."

Only certain model Kineticos are packed resin beds, not all.

"Do not get the Ecominder - it regenerates based on time rather than water usage which ends up wasting water and salt."

The 5600 Econominder is a demand initiated regeneration control valve based on water usage not time. The 5600 mechanical control valve is a timer based control valve.

jcalhoun

10 years agoI was posting the rule of thumb since there are others who are reading this forum. Not everyone in the entire world needs a water treatment system.

dgarmanJAX

Original Author10 years agoThanks for the info aliceinwonderland_id and justalurker. Based on the feedback you gave, I have a few more questions.

At this point, I think the decision will be between the 5600 and 7000 series. In looking at the 7000, it appears to only come in the SXT electronic option. Is there an Econominder version for the 7000 or not?

Top Basket - is this something that I can ask the vendor to provide or do I have to specifically find one with the basket?

Gravel underbed - same question as the top basket. Most of the ones that I've seen online for sale do not include this, mention this, etc.

2 cubic ft - most of the ones I've been looking at for 48000 grain system are 1.5 cubic ft. How important is it for 2 cu ft?

I have all my necessary 1.25" piping already, so will just use that for install. Shouldn't hurt anything I don't think. Also, I'm making my own bypass in an H configuration. I believe they are full-port, quarter turn valves, so good there.

I have also spoken with a local water softener rep here and gotten some more suggestions that I'd like to run by you. He suggested staying away from the SXT models due to the cost associated with fixing them and also due to living in florida, where there's a lot of humidity and my softener will not be in a temp/humidity controlled area (garage). He also suggested a carbon filtration system to remove the chlorine and chrloramine in the water, which I understand. The model systems they sell are the same 5600 and a 9400 model, but are more expensive than what I can buy online, so not sure why the added cost. I was also told that their 5600 system is only a 24000 grain system and based on my hardness, would regenerate every 3 days or so. Their 9400 system is a 32000 grain system and would regenerate every 5 or 6 days on average. Is this accurate? How many grain system do I need to regenerate at a desired interval and what is that interval?

Also wanted to ask if you had suggestions for where to buy? I've seen Affordable Water, Quality Water for Less, etc and they all seem to be about the same price.

Thanks again for your help with this.

User

10 years agoWhen we size a softener we try for a balance between water and salt efficiency. On city water, we try to keep the time between regens a little longer to avoid additional damage to the resin as it is already stressed from the chlorine/chloramine used for disinfection. Generally, that balance point lies at 6 lb salt/cuft resin, regenerating approximately every 7 days.

With your water conditions, a 2 cuft softener (sometimes called 64,000 grain by vendors) will regenerate every 7-8 days at a salt dose of 6 lb/cuft. A 1.5 cuft softener would regen every 5-6 days. Salt usage would be the same either way, but water usage would be higher with the smaller softener.

A 0.75 or 1.0 cuft softener would be too small for several reasons:

3-4 times the water use due to the more frequent regenerations.

A family of four is likely to exceed the maximum flow rate of the smaller softeners, resulting in excessive hardness bleed-through

More frequent regenerations results in more wear and tear on the softener valve and the resin - softener life will be much lower.

A carbon system is not necessary, provided you use resin that is 10% crosslinked. Additionally, a carbon system can be detrimental, as removing the disinfectant from the water increases risk of bacterial growth in your plumbing system.

You vendor can and should provide a top basket and gravel at very little charge - these are inexpensive, but necessary items, particularly for larger-diameter softeners. Gravel can be expensive to ship, so many vendors will try to discourage you from its use - don't let them.

I won't recommend any particular vendor as I do not work for or with any of them. You will have to do your research and order from whichever you are most comfortable with. I will, however, help evaluate any bids for you if you would like.

The Fleck 7000sxt valve should do fine with humidity, but should be protected from the elements. If, however, you wish to avoid the electronics, a 5600 Econominder would suffice. It will cause more pressure drop than the 7000sxt due to internal porting size. I would go with the 7000sxt, but it's not my softener. Your call.

User

10 years agoSince you've already decided to deviate from the 1" service line to 1.25" for no good reason the 7000 is the correct choice. A 5600 is a 3/4" valve and a 2 cu ft softener is right at the design limit (12" resin tank diameter) of the 5600.

An electronically controlled valve can be programmed (fine tuned) for the most efficient operation.

The motor in the 5600 Econominder is just as susceptible to damage from water and humidity as the electronics and motor in the 7000. If you're really worried about the electronics you should do something to protect that $1000+ ECU in your car. There is an environmental cover available for the 7000 that will help protect it from the elements.

Also a good idea to get a small (350va or so) computer uninterruptable power supply (UPS) for the softener. It will keep power to the control valve in the event of power spikes, drops, or outages (for a period of time). You would also need to protect this UPS from rain, water, and such.

And DITTO on what Alice already posted... "Install the softener with a three-valve bypass. This will make it so much easier if you ever need to remove the softener for repairs or wish to take it with you when you move. Use full-port, quarter-turn valves".

When you're doing your arithmetic don't forget to add a day for RESERVE.

This post was edited by justalurker on Thu, Jan 23, 14 at 14:45

dgarmanJAX

Original Author10 years agoOK, so I've gone to three of the websites that I've found for these softeners and pulled some details from them that I want to run by you and get your feedback on which one you'd select. They are all the 7000SXT models that we've been discussing, but they come with some slightly different options. Since there's a bunch of info, I'm going to post them as Option 1, Option 2, and Option 3 and am going to put them in separate posts to make easier to read.

Also as FYI - the 1.25" piping that I have to run from my existing 1" water line was suggested by my father-in-law in and effort to make sure the piping we ran would not add restriction to the flow since the softener will do that as well. I understand your point of view on it, but I have the piping already, so just going to run with it.

Thanks

dgarmanJAX

Original Author10 years agoOption 1

This product includes

- Fleck 7000SXT Meter Valve

- Bypass & Plumbing Adapter (As Chosen From Options)

- 12x52 Mineral Tank

- 18x33 Round Salt Tank

- 18" Round Salt Support Plate (Brine Grid)

- 2.00 Cu Ft Hi-Capacity Resin, 8% Crosslink

- Valve-to-Brine Tank Tubing, 6 Ft. x 3/8"

- Brine Tank 2310 Safety Overflow AssemblySystem Specs

- Regen Type: Meter Initiated (0-9,999 gal)

- Timer Type: Electronic

- Cycle Type: 5-Cycle Adjustable

- Electrical Requirements: 24vac/60hz (Plug-In Transformer Included)

- Limited Warranty: 5 yrs Valve & 10 yrs Tanks

- Service Flow Rate: 18.40 gpm @ 15 psi Drop (Std Piston / 1.05" Dist)

- Backwash Rate: 3.50 gpm

- Dimensions (WxDxH): 31x19x61

- Shipping Weight: 160 lbsResin Options

- Hi-Capacity Resin - 8% Crosslink

- ResinTech CG8 (C-249) Resin 64K

- Fine Mesh Resin 64KDistributor Type

- 1.05" STD Distributor

- 32MM HI-FLOW DistributorPlumbing Options

- Bypass, Noryl 0.75" Male NPT

- Bypass, Noryl 1" Male NPT

- Bypass, Noryl 1.25" Male NPT

- Bypass, Noryl 1.5" Male NPTdgarmanJAX

Original Author10 years agoOption 2

Fleck 7000SXT 1.25" metered control with 1.25" distribution system.

- The double backwash feature can be set to backwash before and after the brine draw cycle, eliminating the need for a turbulator.

When salt is rinsed through the resin, the resin beads expand a little and the iron "breaks off".

- This water softener is outdoor rated.

- The 12" x 48" fiberglass tank houses 64,000 grains (2.0 cu ft) of softening resin.

- The softening resins we offer are a high quality 8% bead strength rating and are certified by the Water Quality Assn.

Don't fall for the "salt saver" or "fine mesh" resin claims. If these products worked as promoted, we would be selling them!

- The brine tank includes a brine valve assembly.

- Drain line connector, 10' of drain tubing and 6' of brine tubing are included.

- Soft water soap test kit supplied.

- Unit ships in separate boxes and includes a resin funnel.

- Controls and brine tank have a 5 year warranty.

- The resin tank has a lifetime warranty.

- Rated flow rate is 21 gpm at 15 psi drop.Piping Options

- 0.75" Male Pipe Thread

- 1" Male Pipe Thread

- 1.25" Male Pipe Thread

- 1" & 1.25" Brass Swet

- 1.25" & 1.5" Brass SwetResin Options

- Standard 8% Resin (China)

- Premium 8% Resin (USA)dgarmanJAX

Original Author10 years agoOption 3

The following components are included with our Water Softeners:

- Specified size standard resin tank

- 1.25" riser tube

- Top distributor basket

- Specified amount of High Capacity Resin (with optional resins available)- Fleck 7000SXT Electronic Meter On Demand Control valve with your choice of one of the following Fleck valve connections:

-- 1" NPT PVC

-- 1-1/4" NPT PVC

-- 1-1/4" Brass Sweat (optional $50 connection)

-- Bypass Valve is included- Brine Tanks

-- 15" x 17" x 36" Rectangular or 18" x 33" Round

-- Salt grid

-- 2310 float assembly and safety overflow

-- 4' Fleck valve-to-brine tank tubing

Fleck 7000SXT Electronic 1-1/4 Inch Meter On Demand Control Valve Water Softener 64000 Grain Capacity

- 7000 bypass valve

- 12x48 resin tank

- 2.0 cubic feet of resin

- 13 gpm service flow rate

- 3 gpm backwash flow rate

- Floor Space Required is 28x21x58

- Shipping Weight is 160 lbsConnection Options

- 1" NPT PVC

- 1.25" NPT PVC

- 1.25" Brass SweatResin Options

- NSF Approved High Capacity Cation 8% Crosslink Softening Resin (Imported)

- Purolite C100E High Capacity Cation 8% Crosslink Softening Resin (USA)

- NSF Approved High Capacity Cation 10% Crosslink Softening Resin (Imported)

- Purolite SST60 (Salt Saving Technology) Resin (USA)dgarmanJAX

Original Author10 years agoAlso forgot to ask about a Turbulator and Res Care? From what I can tell, these are needed for Iron and since I don't have any iron, I don't need these???

Thanks

dgarmanJAX

Original Author10 years agoSorry, I keep thinking of questions - what about the size of the brine tank? Any thoughts on what size that should be? Would assume that the smaller would work, just would have to fill it more often. Is that the only issue with a smaller brine tank or is there something else?

Thanks

dgarmanJAX

Original Author10 years agoOK, I think I've found the system that will meet my needs and follow the suggestions you all have provided. Alice, can you please review this and let me know if anything needs modification?

Thanks

1ea Fleck 7000SXT Electronic 1-1/4 Inch Metered Water Softener 64,000 Grain Capacity

7000 bypass valve

Top Basket

12x48 resin tank2.0 cubic feet of NSF Approved High Capacity Cation 10% Crosslink Softening Resin

Gravel Support Media13 gpm service flow rate

3 gpm backwash flow rateSelected options:

Fleck Valve Connection: 1-1/4 Inch NPT PVCNo Bypass Valve

Tank Color Option: Almond

15x17x36 Rect Brine Tank w/salt grid & 2310 Float Assembly

Our Price............................................. $665.00User

10 years agoSpecs look good, as does the price. The only thing I might add as a redundancy would be a noryl bypass, but you are installing a bypass so it's not strictly necessary.

Once you have the softener on site, I need the BLFC size and the specific resin brand/type to offer programming details.

dgarmanJAX

Original Author10 years agoAlice, thanks again for the help and information. Order placed, should arrive some time next week. Will holler when I have it hooked up and ready to go.

User

10 years agoI have not seen a Fleck 7000SXT (softener) valve ship from Fleck without it's Noryl bypass. Whether or not the seller's drop shipper removes the included bypass and charges extra for it as an accessory or special orders the valve without a bypass is a matter of ethical business practice that should be considered.

Rather than the absolute lowest price driving the decision the OP should pick the highest quality of each component. The odds are whatever online seller the OP chooses they will be using the drop-shipper (Nelsen Corp) as a supplier and Nelsen Corp squeezes every cent of profit they can out of every sale by supplying the absolute cheapest parts and components they can get. That includes no name top and bottom baskets, Nelsen Corp anonymous resin, and resisting including gravel at no charge. I don't know whether Nelsen Corp supplies the high quality Clack brine tanks or a cheap look alike and whether they include the salt grids. They used to supply the Fleck 2310 safety floats and I hope they still do.

I would SPECIFY the Fleck 7000 with it's Noryl bypass and would ALSO install a three ball valve bypass for reasons previously stated.

A few cents spent on a real Fleck top and bottom basket can save the OP from a real PITA repair down the road and choosing brand name resin is a no brainer whether it costs extra or not.

This post was edited by justalurker on Fri, Jan 24, 14 at 21:11

dgarmanJAX

Original Author10 years agoAlice, finally getting ready to complete the hookup of the softener this weekend and am trying to gather the info you requested. The resin is Nelsen CR10. I have two 1.0 Cubic feet bags of the resin.

With regard to the BLFC, I have a 3/8" Brine Kit for connecting the brine tank. Is that equivalent to BLFC?

As for programming the model, it looks like I have the following settings that need to be configured (for some of these, I'm going to put what I think, so please correct):

Display Format - GAL

Valve Type - dF2b??

Control Type - ?

Unit Capacity - ?

Hardness - 20

Reserve Selection - ?

Safety Factor - ?

Fixed Reserve Capacity - ?

Variable Reserve - ?

Day Override - ?

Regen Time - ?

Regen Cycle Step Times - ?

Current Day - ?

Flow Meter Size - ?

Meter Pulse Setting Generic - ?Thanks again for your time and help with this.

User

10 years ago3/8" only specifies the line size. The BLFC is an orifice that could be 0.125, 0.25, 0.5 or 1.0 gpm. There should be a sticker on the back of the valve. It will be about 3/4" x 3/4" and typically blue in color, although it could be black, white or red.

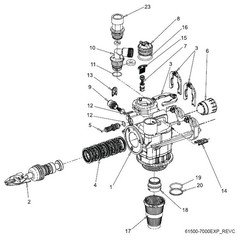

Here is a a blow-up of the valve. The BLFC is #9 on the drawing.

This post was edited by aliceinwonderland_id on Fri, Feb 7, 14 at 12:32

User

10 years agoEnter Master Programming Mode

DF=Gal

VT = St2b (or Df2b)

CT=Fd

NT=1

C=42

H=20

RS=SF

SF=15

RC=0 (You are using a % reserve rather than a fixed reserve)

CR=0 (DonâÂÂt use variable reserve with iron in your water)

DO=10

RT=2:00 (or another convenient time when you wonâÂÂt be using water for a couple of hours)

Regeneration cycle step times

BW1=10

BD=60

BW2=7

RR=10

BF=32Ensure all days are set to ON, unless you have a specific day of the week when you do not want the softener to regen.

CD doesnâÂÂt matter unless you set a day to OFF in step 14.

FM You shouldnâÂÂt have to change this

doesnâÂÂt matter

Exit Master Programming Mode.

Pour 5 gallons of water into the brine tank. Add salt.

Reset your clock to actual time.

At this point itâÂÂs a good idea to force the softener to step through the regen steps. There is no need to allow each step to complete. Just leave it in each step long enough to verify that the valve has changed position then move on to the next until you are back in service mode.

Enjoy your soft water.

dgarmanJAX

Original Author10 years agoAlice, thanks for the info. One last quick question before i get it all setup - does it matter how much salt I put into the brine tank? I'll add the 5 gallons of water first, but wasn't sure how much salt I need to keep in the tank.

Thanks

User

10 years agoIf you live in a high humidity area, just enough salt to cover the water. Otherwise, you may keep as much salt in the brine tank as you would like. Regardless, it is a good idea to glance into the tank at least every couple of weeks.

dgarmanJAX

Original Author10 years agoAlice, thanks again for all your help with this. I was able to get everything setup and configured and have been using our soft water since this past weekend. I was able to manually step through the regeneration cycle and everything worked as expected. So at this point, no issues. Will look forward to the upcoming automatic regeneration. Just so I'm clear on something - it should regenerate at 2AM the night it runs out of water (meaning all gallons used based on settings) or on the 10th night (whichever comes first) correct?

dgarmanJAX

Original Author10 years agoAlice, went through first scheduled regeneration without any issues and softener has been working great. I do however have a question. After the softener regenerated I looked in the brine tank and the water in there is now about 3-4 inches above the salt. When I initially setup everything I added 5 gallons of water and then two bags of salt. The water at that time was pretty well under the salt. But now it's several inches above the salt. Is that correct or is there something wrong that I need to correct?

Thanks

User

10 years agoIt is most likely fine fine. Some of the salt has been used and the salt has settled a bit. Just to ensure all is functioning properly, mark the water level with a piece of tape and check it again after the next regen. It should remain about the same.

tim12345

10 years agodgarmanJAX:

Are you willing to tell me where you purchased from? It sounds like I'm about 2 months behind you in that I'm struggling to find the 10% resin, the basket, gravel, etc.

dgarmanJAX

Original Author10 years agoTim it was Ohio Pure Water company. They have the 10% cross link resin and also were able to do gravel and top basket without any issues. Everything was easy with them and came as ordered.

User