Building bookshelves.

apoem

18 years ago

Related Stories

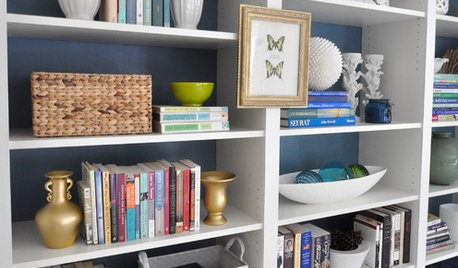

DECORATING GUIDESAfternoon Project: Declutter Your Bookshelves

Overstuffed bookshelves can easily turn into an eyesore. These shelf-clearing projects are bound to help

Full Story

ORGANIZINGDesign Details: Inspired by Expedit Bookshelves

Ikea's Classic Storage Cubes Work All Over the Home

Full Story

BASEMENTSWhat Lies Beneath: Cool Things to Build Underground

Ingenious designers are going below the surface in some amazing — and surprising — ways

Full Story

DECORATING GUIDES6 Focal Points to Build a Beautiful Interior Around

Not sure what element to make the attention getter in your room? Find some great choices here

Full Story

ROOM OF THE DAYRoom of the Day: Berkeley Living Room Builds on History and Style

Rich and dark woods, oversized furniture, layered lighting and intriguing artwork give this California room a comfortable sophistication

Full Story

ORGANIZINGHow to Design Built-Ins That Fit Your Needs

Tips for designing built-in bookshelves and storage

Full Story

CONTEMPORARY HOMESHouzz Tour: Reading Shapes a Seattle Home

Written words drive the design of a house for aging in place, from a plethora of bookshelves to a personal word wall

Full Story

BATHROOM DESIGN10 Living Room Touches to Bring to the Bath

Go ahead, borrow those bookshelves. Unexpected elements can boost interest and comfort in your bathroom

Full Story

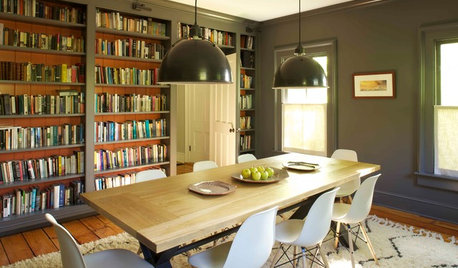

DECORATING GUIDESDinner and a Good Book: 12 Double-Duty Dining Rooms

Create your own library-inspired reading room by pairing a dining table with bookshelves

Full Story

GREEN BUILDINGHouzz Tour: Off-the-Grid Island Home Circles a Sunny Courtyard

A circular home is a cozy spot for gardening, woodworking and plenty of reading

Full StorySponsored

Columbus Design-Build, Kitchen & Bath Remodeling, Historic Renovations

More Discussions

rjvt

talley_sue_nyc

Related Professionals

Annapolis Custom Closet Designers · Bethesda Custom Closet Designers · South Elgin Custom Closet Designers · Verona Custom Closet Designers · Pleasant Hill Custom Closet Designers · Kapolei Custom Closet Designers · Rosaryville Interior Designers & Decorators · Lewisville Home Builders · Placentia Home Builders · Fairfax Carpenters · Albany Carpenters · Birmingham Carpenters · Miller Place Carpenters · Saint Charles Carpenters · Summerlin Carpenterscloudy_christine