Refinishing old red oak floors with carpet glue

jeffcat

12 years ago

Related Stories

GREAT HOME PROJECTSWhat to Know Before Refinishing Your Floors

Learn costs and other important details about renewing a hardwood floor — and the one mistake you should avoid

Full Story

WOODWoodipedia: Make a Solid Choice With Oak

Forget those low-end products of old. Red and white oak today are beautiful, versatile and relatively inexpensive

Full Story

REMODELING GUIDES11 Reasons to Love Wall-to-Wall Carpeting Again

Is it time to kick the hard stuff? Your feet, wallet and downstairs neighbors may be nodding

Full Story

REMODELING GUIDESYour Floor: An Introduction to Solid-Plank Wood Floors

Get the Pros and Cons of Oak, Ash, Pine, Maple and Solid Bamboo

Full Story

UPHOLSTERYThe Perks and Perils of Reupholstering Old Furniture

Secondhand upholstered pieces can add character to a room, but beware of bugs, snakes and hidden costs

Full Story

HOUSEKEEPINGOut, Darn Spot! Tips for Removing Carpet Stains

Know the right solutions and when to use them to prevent stains from pets, soda, chocolate, blood and more

Full Story

MOST POPULARHow to Reface Your Old Kitchen Cabinets

Find out what’s involved in updating your cabinets by refinishing or replacing doors and drawers

Full Story

FLOORS10 Ways to Make the Most of Your Home’s Original Floors

Save yourself the cost of replacing your old floorboards with these tips for a new finish

Full Story

HOUZZ TOURSMy Houzz: Bold Wallpaper Kicks Up a Century-Old Craftsman

Design risks pay off in a Seattle bungalow that combines fearless patterns with subtler colors and a sophisticated practicality

Full Story

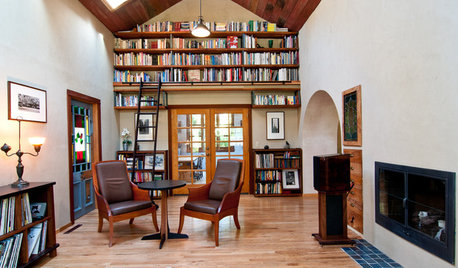

HOUZZ TOURSMy Houzz: Old-World European Flair in Oregon

Custom woodwork, stained glass and Arts and Crafts touches create warm, earthy interiors in a ranch-style home

Full StoryMore Discussions

columbusguy1

Christopher Nelson Wallcovering and Painting

Related Professionals

Amherst Kitchen & Bathroom Designers · Carlisle Kitchen & Bathroom Designers · Fresno Kitchen & Bathroom Designers · Grafton Kitchen & Bathroom Designers · Riviera Beach Kitchen & Bathroom Designers · West Virginia Kitchen & Bathroom Designers · Eagle Mountain Kitchen & Bathroom Remodelers · Jacksonville Kitchen & Bathroom Remodelers · Kuna Kitchen & Bathroom Remodelers · Lyons Kitchen & Bathroom Remodelers · Rancho Palos Verdes Kitchen & Bathroom Remodelers · Princeton Kitchen & Bathroom Remodelers · Carney Architects & Building Designers · North Chicago Architects & Building Designers · Spring Valley Architects & Building Designersslateberry

sombreuil_mongrel

brickeyee

ks_toolgirl

brickeyee

John Tebbs

brickeyee

Fori

jeffcatOriginal Author

brickeyee

jeffcatOriginal Author

ks_toolgirl

brickeyee

sautesmom Sacramento