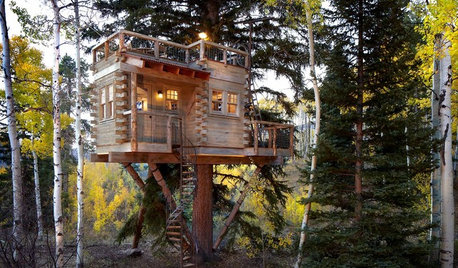

What do you call this wood work?

katie8422

13 years ago

Related Stories

WALL TREATMENTSHouzz Call: Show Us Your Feature Wall

Have you used bold paint, reclaimed wood, living plants or something else to jazz up a wall in your home? We want to see it

Full Story

LIFEHouzz Call: Who'll Post the First Snow Photo of 2013?

If the weather's been flaky in your neck of the woods, please show us — and share how you stay warm at home

Full Story

LIFEShare Your Winter Storm Jonas Photos and Survival Tips!

Let’s see your pictures and hear your ideas on how you’re keeping your house warm and staving off cabin fever

Full Story

HOUZZ TOURSHouzz Call: Show Us Your Industrial Loft!

Bring on the brick and metal. If you live in a converted warehouse or an edgy loft, we’d love to see it

Full Story

GREEN BUILDINGHouzz Call: What Have You Salvaged for Home Use?

If your floors, furniture, exterior materials or other home elements have a past life, we'd like to hear the story

Full Story

Houzz Call: Show Us Your Paint Makeovers

Let your newly repainted house or room do the "How d'ya like me now?" strut right here — it might just be featured in an upcoming ideabook

Full Story

HOUZZ CALLShow Us the Best Kitchen in the Land

The Hardworking Home: We want to see why the kitchen is the heart of the home

Full Story

TREE HOUSESHouzz Call: Show Us Your Well-Designed Treehouse or Tree Fort!

Got a great treehouse or tree fort? We want to see it! Post yours in the Comments and we’ll feature the best in a future article

Full Story

FUN HOUZZHouzz Call: Tell Us About Your Dream House

Let your home fantasy loose — the sky's the limit, and we want to hear all about it

Full Story

KITCHEN DESIGNHouzz Call: Tell Us About Your First Kitchen

Great or godforsaken? Ragtag or refined? We want to hear about your younger self’s cooking space

Full Story

karinl

sombreuil_mongrel

Related Professionals

Highland Kitchen & Bathroom Designers · Plymouth Kitchen & Bathroom Designers · South Barrington Kitchen & Bathroom Designers · Bay Shore Kitchen & Bathroom Remodelers · Cocoa Beach Kitchen & Bathroom Remodelers · Fort Myers Kitchen & Bathroom Remodelers · Gardner Kitchen & Bathroom Remodelers · Green Bay Kitchen & Bathroom Remodelers · Overland Park Kitchen & Bathroom Remodelers · Phoenix Kitchen & Bathroom Remodelers · Sicklerville Kitchen & Bathroom Remodelers · Southampton Kitchen & Bathroom Remodelers · Joppatowne Kitchen & Bathroom Remodelers · Prairie Village Kitchen & Bathroom Remodelers · Martinsville Architects & Building Designersyoung-gardener

Carol_from_ny

mkroopy

katie8422Original Author

concretenprimroses

brickeyee

katie8422Original Author

sombreuil_mongrel

kframe19

slateberry

brickeyee

fuzzywuzzer

la_koala

kframe19

katie8422Original Author

columbusguy1

katie8422Original Author

karinl

palimpsest

columbusguy1