Copper sheet to cover a window sill?

fandlil

16 years ago

Featured Answer

Sort by:Oldest

Comments (6)

fandlil

16 years agoRelated Professionals

Denver Furniture & Accessories · Greer Furniture & Accessories · Memphis Furniture & Accessories · Woodbury Furniture & Accessories · Lomita Interior Designers & Decorators · Arkansas City General Contractors · Clarksville General Contractors · Easley General Contractors · Foothill Ranch General Contractors · Medford General Contractors · Seal Beach General Contractors · Largo Siding & Exteriors · South Windsor Siding & Exteriors · Iowa City Siding & Exteriors · Lansing Siding & Exteriorsgreen-zeus

16 years agosawdust_maker

16 years agobrickeyee

16 years agoelisea2

8 years ago

Related Stories

CURB APPEALModern Materials: Copper, Architecture's Natural Beauty

The rich patina is just the beginning — copper for home exteriors is strong, shapable and highly recyclable

Full Story

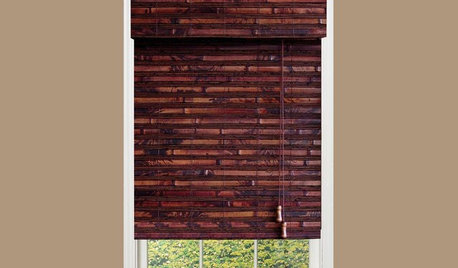

PRODUCT PICKSGuest Picks: A Whole Lotta Wonderful Window Coverings

Blinds, drapes, shades and curtain rods to give your windows a polished, put-together look

Full Story

DECORATING GUIDESHow to Work With Awkward Windows

Use smart furniture placement and window coverings to balance that problem pane, and no one will be the wiser

Full Story

TRADITIONAL STYLEDecorating With Antiques: Luxurious Linens

Bring quality, comfort and a sense of old-world romance to your rooms with vintage tablecloths, sheets, napkins and more

Full Story

WINDOWS11 Ways to Create Indoor-Outdoor Connections

Expand nature's soothing embrace with sliding doors, covered porches, generous windows and more

Full Story

KITCHEN DESIGNGreat Solutions for Low Kitchen Windowsills

Are high modern cabinets getting you down? One of these low-sill workarounds can help

Full Story

DECORATING GUIDESHow to Get Your Window Treatment Right

Here's the lingo to know to get the draperies you really want

Full Story

HOUSEKEEPINGThe Best Way to Get Your Windows Spotlessly Clean

Learn the pros’ tips and tricks for cleaning windows and getting them streak-free

Full Story

REMODELING GUIDESWhich Window for Your World?

The view and fresh air from your windows make a huge impact on the experience of being in your house

Full Story

DECORATING GUIDESThe Art of the Window: Drapery Solutions for Difficult Types and Shapes

Stymied by how to hang draperies on a nonstandard window? Check out these tips for dressing 10 tricky window styles

Full StorySponsored

green-zeus