in-expensive welder

erstanfo

19 years ago

Related Stories

HOUZZ TVHouzz TV: Cool Reclaimed Wood Projects Fill a Craftsman’s Home

Using barn wood, beadboard and beams, this homeowner has crafted furnishings and features for his family’s Chicago home

Full Story

LIGHTING10 Ways With Wall Lights That Don’t Need to Be Wired In

Learn how to add illumination to your home without carving into the walls

Full Story

KITCHEN DESIGNKitchen of the Week: Taking Over a Hallway to Add Needed Space

A renovated kitchen’s functional new design is light, bright and full of industrial elements the homeowners love

Full Story

HOUZZ TOURSHouzz Tour: Family Reimagines the New England Farmhouse

See how a family in Maine takes apart a falling-down barn and uses the timber for an affordable new family home

Full Story

MOVINGHow to Avoid Paying Too Much for a House

Use the power of comps to gauge a home’s affordability and submit the right bid

Full Story

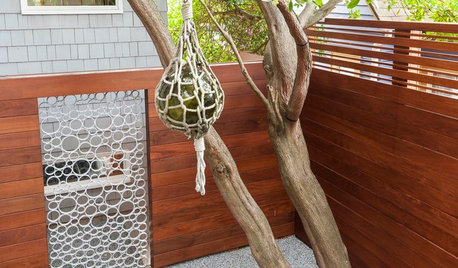

FENCES AND GATESA Designer Uses PVC Pipe to Cast a Modern Garden Gate

Landscape designer Scot Eckley walks us through the process of creating a custom aluminum ring gate

Full Story

BEFORE AND AFTERSKitchen Rehab: Don’t Nix It, Fix It

A small makeover makes a big impact in a traditional kitchen in Atlanta with great bones

Full Story

MATERIALSAre You a Maker? Show Us Your Favorite Tool or Material

Houzz Call: A tool or material can be a maker’s best friend. We’d like to see your favorite — and what it helps you achieve

Full Story

KITCHEN DESIGNTrick Out Your Kitchen Backsplash for Storage and More

Free up countertop space and keep often-used items handy by making your backsplash more resourceful

Full Story

KITCHEN DESIGNKitchen of the Week: Salvage Meets High End in Vancouver

Reclaimed fir floors and a salvage-yard gate cozy up to choice appliances in a warm and sophisticated Canadian kitchen

Full Story

kbeitz

swpro11

Related Professionals

Aurora General Contractors · Clarksville General Contractors · Enumclaw General Contractors · Fairview General Contractors · Forest Grove General Contractors · Great Falls General Contractors · Midlothian General Contractors · Montclair General Contractors · Reisterstown General Contractors · Rossmoor General Contractors · San Marcos General Contractors · Troy General Contractors · University Park General Contractors · Shoreline Siding & Exteriors · Spartanburg Siding & Exteriorsjohn_in_ma

DirtyEd

chadtoolio

horseman1

wasmeneh

blacksmithman

kbeitz

hunter_tx

kbeitz

hunter_tx

ROSCOESTAN

Tsavah

horseman1

DNT1

spambdamn_rich

backyardbill

badmugzz_gmail_com

m_gardner43_yahoo_com