Best blade for cutting aluminum?

californian

16 years ago

Related Stories

PATIOSPatio Details: A Custom Aluminum Arbor Cools Things Down in Texas

Panels in the roof have leaf pattern cutouts that create dappled shade and a calm, relaxed ambience

Full Story

THE ART OF ARCHITECTURELaser-Cut Focus: The Future of Design Is Here

Discover how this laser technology can make almost any pattern a reality

Full Story

KITCHEN DESIGNKitchen Counters: Try an Integrated Cutting Board for Easy Food Prep

Keep knife marks in their place and make dicing and slicing more convenient with an integrated butcher block or cutting board

Full Story

HOME OFFICESQuiet, Please! How to Cut Noise Pollution at Home

Leaf blowers, trucks or noisy neighbors driving you berserk? These sound-reduction strategies can help you hush things up

Full Story

DIY PROJECTSHow to Make a Festive Paper-Cut Ornament

Add a personal touch to your Christmas tree this year with this pretty handmade decoration

Full Story

ACCESSORIESEasy Green: Cut Electricity Use With 15 Unplugged Home Devices

Crank up the energy savings, courtesy of household items that come into power the old-fashioned way: manually

Full Story

GARDENING GUIDES7 Ecofriendly Gardening Ideas That Also Cut Chore Time

Spend less time weeding, less money watering and more moments just sitting back and enjoying your healthy garden

Full Story

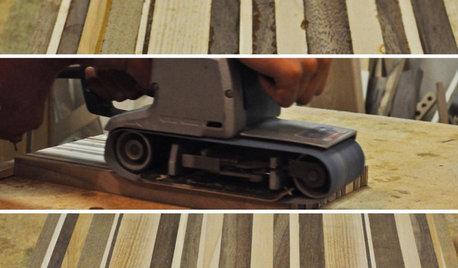

DIY PROJECTSFashion a High-Quality Cutting Board From Scrap Wood

Waste not, want not. This DIY project saves scraps from the landfill, hones your woodworking skills and produces a gorgeous kitchen piece

Full Story

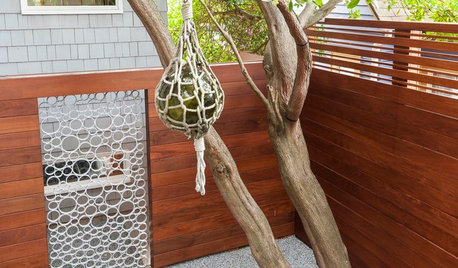

FENCES AND GATESA Designer Uses PVC Pipe to Cast a Modern Garden Gate

Landscape designer Scot Eckley walks us through the process of creating a custom aluminum ring gate

Full Story

MATERIALSAn Architect Shares His Go-To Materials

Aluminum doors, porcelain tiles, polished concrete. Here are the features and finishes this professional returns to time and again

Full StorySponsored

flgargoyle

californianOriginal Author

Related Professionals

Frisco Furniture & Accessories · Glenview Furniture & Accessories · Rancho Santa Margarita Furniture & Accessories · Stamford Furniture & Accessories · Linton Hall Interior Designers & Decorators · Mansfield Interior Designers & Decorators · Bay City General Contractors · Bryan General Contractors · Lakewood General Contractors · Nampa General Contractors · Overlea General Contractors · Security-Widefield General Contractors · Berkeley Siding & Exteriors · Kirkland Siding & Exteriors · Round Rock Siding & Exteriorsadriand123