How to determine Amps on an Arc Welder

Salkeld_Farms

18 years ago

Related Stories

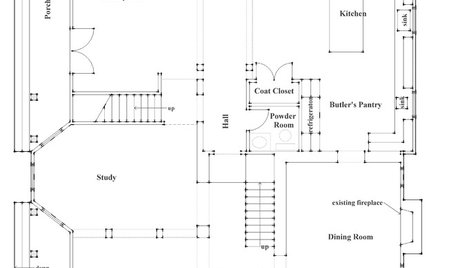

REMODELING GUIDESHow to Read a Floor Plan

If a floor plan's myriad lines and arcs have you seeing spots, this easy-to-understand guide is right up your alley

Full Story

GREEN BUILDINGInsulation Basics: Heat, R-Value and the Building Envelope

Learn how heat moves through a home and the materials that can stop it, to make sure your insulation is as effective as you think

Full Story

CONTEMPORARY HOMESHouzz Tour: At Home With a Stunning View

Wood siding and contemporary features combine to create a family’s dream home in Sydney

Full Story

LANDSCAPE DESIGN24 Garden Paths to Inspire Memorable Journeys

Winding or straight, narrow or wide, densely or sparsely planted — there’s more than one way to design a walk

Full Story

BATHROOM DESIGNThe Case for a Curbless Shower

A Streamlined, Open Look is a First Thing to Explore When Renovating a Bath

Full Story

LIGHTING10 Ways to Get Your Lighting Right

Learn how to layer table lamps, floor lamps and overhead fixtures to get the lighting you need and the mood you want

Full Story

MOVINGHow to Avoid Paying Too Much for a House

Use the power of comps to gauge a home’s affordability and submit the right bid

Full Story

DECORATING STYLESIs Your Home Ready for a 1970s Revival?

Seventies chic is a trend that’s been brewing for some time, but this year it could hit big — with a few modern tweaks

Full Story

KITCHEN DESIGNGet a Grip on Kitchen Cabinets With the Right Knobs and Pulls

Here's how to pair the right style, type and finish of cabinet hardware with your kitchen style

Full Story

SMALL SPACES11 Design Ideas for Splendid Small Living Rooms

Boost a tiny living room's social skills with an appropriate furniture layout — and the right mind-set

Full StorySponsored

Pooh Bear

gooseberry_guy

Related Professionals

Dallas Furniture & Accessories · Walnut Creek Furniture & Accessories · Fountainebleau Furniture & Accessories · Temple Terrace Furniture & Accessories · Fountain Hills Interior Designers & Decorators · Beloit General Contractors · Fort Pierce General Contractors · Hartford General Contractors · Seguin General Contractors · Selma General Contractors · Uniondale General Contractors · Westchester General Contractors · Southampton Siding & Exteriors · Tustin Siding & Exteriors · Weymouth Siding & Exteriorsmla2ofus

john_in_ma