How to cut open an oil tank?

amderin

14 years ago

Related Stories

HOUZZ TOURSHouzz Tour: Design Moves Open Up a Melbourne Cottage

A renovation rejiggers rooms and adds space. Suspended shelves and a ceiling trick make the living area feel bigger

Full Story

KITCHEN OF THE WEEKKitchen of the Week: From Dated and Isolated to Open and User-Friendly

Rethinking spaces allows an active California family to enjoy a modern, smartly designed kitchen and dining area

Full Story

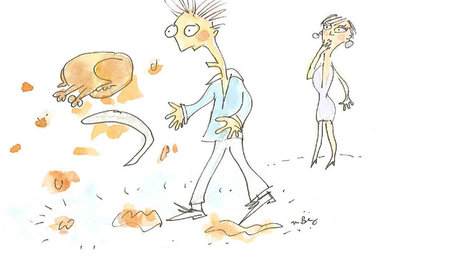

MOST POPULARThanksgiving Tales: When the Turkey Tanks

Houzz readers prove adept at snatching victory from the jaws of entertaining defeat

Full Story

MOST POPULARIs Open-Plan Living a Fad, or Here to Stay?

Architects, designers and Houzzers around the world have their say on this trend and predict how our homes might evolve

Full Story

BATHROOM DESIGNSee the Clever Tricks That Opened Up This Master Bathroom

A recessed toilet paper holder and cabinets, diagonal large-format tiles, frameless glass and more helped maximize every inch of the space

Full Story

HOUSEKEEPINGHow to Clean Your Cutting Boards

Learn the best techniques for cleaning and sanitizing wood and plastic cutting boards

Full Story

KITCHEN STORAGEPartly Open Shelving: The Case for Doorless Cabinets

Build in some display areas, create a colorful design feature and make better use of awkward spaces with open shelves

Full Story

LIGHTINGSo You Bought a Cave: 7 Ways to Open Your Home to Light

Make the most of the natural light your house does have — and learn to appreciate some shadows, too

Full Story

KITCHEN CABINETSWhy I Combined Open Shelves and Cabinets in My Kitchen Remodel

A designer and her builder husband opt for two styles of storage. She offers advice, how-tos and cost info

Full Story

KITCHEN DESIGNOpen vs. Closed Kitchens — Which Style Works Best for You?

Get the kitchen layout that's right for you with this advice from 3 experts

Full Story

alphonse

izzie

Related Professionals

Paramus Furniture & Accessories · Farmington Furniture & Accessories · Clark Furniture & Accessories · Pleasant Grove Furniture & Accessories · Kingsburg Furniture & Accessories · Stanford Interior Designers & Decorators · Eagan General Contractors · Millville General Contractors · Panama City General Contractors · Saint Andrews General Contractors · Elizabeth Siding & Exteriors · Greenville Siding & Exteriors · Philadelphia Siding & Exteriors · Waukegan Siding & Exteriors · Wethersfield Siding & Exteriorspjb999

alphonse

amderinOriginal Author

pjb999

fixizin

brickeyee

brickeyee

oldasrocks