Welding copper

scarlettt

18 years ago

Related Stories

CURB APPEALModern Materials: Copper, Architecture's Natural Beauty

The rich patina is just the beginning — copper for home exteriors is strong, shapable and highly recyclable

Full Story

MODERN ARCHITECTUREDesign Workshop: Modern Metal Shingle Style

Steel, copper and zinc shingles take siding to new heights, with less maintenance than their wooden cousins

Full Story

LOFTSHouzz Tour: 12 Years of Tinkering Produce an Amazingly Artful Loft

Major DIY efforts turn 3 units in a former Portland factory into a single home brimming with personality

Full Story

THE ART OF ARCHITECTUREDesign Workshop: Put Industrial Mesh to Work Around the Home

From open gratings to fine weaves, commercial metal mesh is a durable and beautiful choice for residences too

Full Story

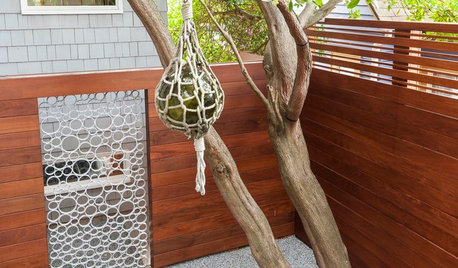

FENCES AND GATESA Designer Uses PVC Pipe to Cast a Modern Garden Gate

Landscape designer Scot Eckley walks us through the process of creating a custom aluminum ring gate

Full Story

WINDOWSSteel-Framed Windows Leap Forward Into Modern Designs

With a mild-mannered profile but super strength, steel-framed windows are champions of design freedom

Full Story

FURNITUREForever Furniture: A Buyer’s Guide to the Dining Table

There comes a time when a make-do piece of furniture won’t do. We give you a leg up on choosing the right table for you

Full Story

ARTAt Home With Art: Suspended Sculptures Heighten the Possibilities

Draw the eye in unexpected ways with 3D artwork hung from above

Full Story

GREEN BUILDINGHouzz Call: What Have You Salvaged for Home Use?

If your floors, furniture, exterior materials or other home elements have a past life, we'd like to hear the story

Full Story

GARDENING AND LANDSCAPINGCharm Up Your House With Windowboxes

Plant Some Living Color Right Outside Your Window

Full Story

brickeyee

sudsmaster

Related Professionals

Miami Furniture & Accessories · Rock Hill Furniture & Accessories · Moraga Furniture & Accessories · Enfield General Contractors · Groton General Contractors · Hanford General Contractors · Mankato General Contractors · Redan General Contractors · Rossmoor General Contractors · Saginaw General Contractors · Winton General Contractors · Kennewick Siding & Exteriors · Lebanon Siding & Exteriors · Orange County Siding & Exteriors · Wayne Siding & ExteriorsscarletttOriginal Author

brickeyee

sudsmaster

brickeyee

lazypup