Returning Bosch Nexxt

ak-titan

17 years ago

Related Stories

CRAFTSMAN DESIGNKitchen of the Week: Kitchen Returns to the Craftsman Era

Minnesota designers incorporate fine woodwork, Arts and Crafts stenciling, and handmade lights and tiles into their new space

Full Story

PETSHouzz Pets Survey: Who Rules the House — Dogs or Cats?

New data shows that pets make people happy, and pet owners love spending big to return the favor

Full Story

FARMHOUSESNew This Week: 2 Charming Farmhouse Kitchens With Modern Convenience

These spaces have all of today’s function with yesteryear’s simplicity and character

Full Story

KITCHEN DESIGNStandouts From the 2014 Kitchen & Bath Industry Show

Check out the latest and greatest in sinks, ovens, countertop materials and more

Full Story

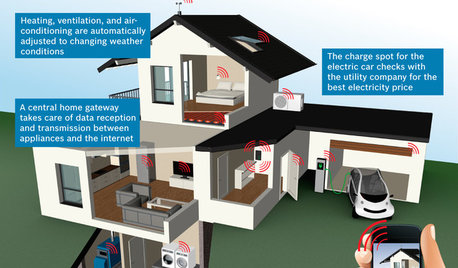

THE HARDWORKING HOMECES 2015: Inching Toward a Smarter Home

Companies are betting big on connected devices in 2015. Here’s a look at what’s to come

Full Story

GREEN BUILDINGWater Sense for Big Savings

Keep dollars in your pocket and preserve a precious resource with these easy DIY strategies

Full Story

TASTEMAKERSPro Chefs Dish on Kitchens: Michael Symon Shares His Tastes

What does an Iron Chef go for in kitchen layout, appliances and lighting? Find out here

Full Story

KITCHEN DESIGNHow to Choose the Right Hood Fan for Your Kitchen

Keep your kitchen clean and your home's air fresh by understanding all the options for ventilating via a hood fan

Full Story

KITCHEN DESIGNKitchen Remodel Costs: 3 Budgets, 3 Kitchens

What you can expect from a kitchen remodel with a budget from $20,000 to $100,000

Full Story

HOUSEKEEPINGHow to Clean Stainless Steel

Protect this popular kitchen material with a consistent but gentle cleaning routine

Full StorySponsored

Industry Leading Interior Designers & Decorators in Franklin County

More Discussions

sshrivastava

lei1234

Related Professionals

Honolulu Kitchen & Bathroom Remodelers · Beaumont Cabinets & Cabinetry · Darby Custom Closet Designers · Appleton Custom Closet Designers · Camp Springs Custom Closet Designers · Saugus Custom Closet Designers · Eldersburg Flooring Contractors · Fort Pierce Flooring Contractors · Highlands Ranch Flooring Contractors · Inver Grove Heights Flooring Contractors · Lynbrook Flooring Contractors · Mahwah Flooring Contractors · Palm Valley Flooring Contractors · South Peabody Flooring Contractors · Troy Flooring Contractorsbenbow

jjam

asolo

ak-titanOriginal Author

asolo

rosecmd

wblynch

ak-titanOriginal Author

mrsee

asolo

dross

ojaijohn