Basic Maintainence

vampiressrn

13 years ago

Related Stories

DECKSDecking Materials Beyond Basic Lumber

Learn about softwoods, tropical hardwoods, composites and more for decks, including pros, cons and costs

Full Story

GREEN BUILDINGGoing Solar at Home: Solar Panel Basics

Save money on electricity and reduce your carbon footprint by installing photovoltaic panels. This guide will help you get started

Full Story

GREEN BUILDINGInsulation Basics: Heat, R-Value and the Building Envelope

Learn how heat moves through a home and the materials that can stop it, to make sure your insulation is as effective as you think

Full Story

MOVINGYour First Home: Beautiful Basics and Multitaskers for Every Room

Here’s what to choose and what to avoid when outfitting a new house

Full Story

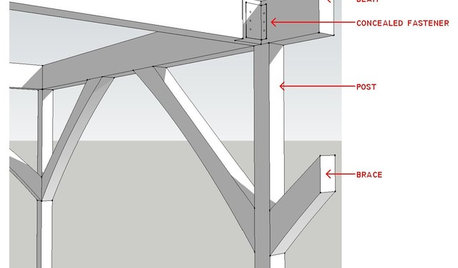

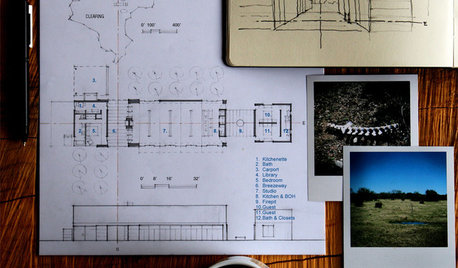

REMODELING GUIDESKnow Your House: Post and Beam Construction Basics

Learn about this simple, direct and elegant type of wood home construction that allows for generous personal expression

Full Story

ARCHITECTUREDesign Practice: The Basics of Marketing Your Business

Pro to pro: Attract clients and get paying work by drawing attention to your brand in the right places

Full Story

GREEN BUILDINGInsulation Basics: Designing for Temperature Extremes in Any Season

Stay comfy during unpredictable weather — and prevent unexpected bills — by efficiently insulating and shading your home

Full Story

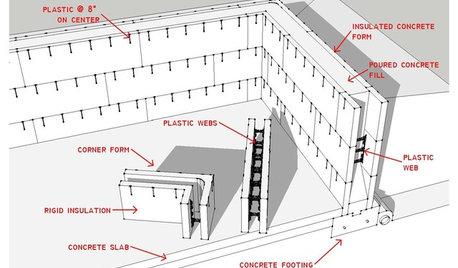

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

GREEN BUILDING6 Green-Roof Myths, Busted

Leaky, costly, a pain to maintain ... nope, nope and nope. Get the truth about living roofs and see examples from simple to elaborate

Full Story

KITCHEN CABINETS9 Ways to Get Low-Maintenance Kitchen Cabinets

Save valuable elbow grease and time with these ideas for easy-to-maintain cabinets

Full Story

dadoes

User

Related Professionals

Glens Falls Kitchen & Bathroom Designers · Beachwood Kitchen & Bathroom Remodelers · Chicago Ridge Kitchen & Bathroom Remodelers · Creve Coeur Kitchen & Bathroom Remodelers · Fort Washington Kitchen & Bathroom Remodelers · Londonderry Kitchen & Bathroom Remodelers · Superior Kitchen & Bathroom Remodelers · Radnor Cabinets & Cabinetry · Salisbury Cabinets & Cabinetry · North Plainfield Cabinets & Cabinetry · Aurora Custom Closet Designers · Anaheim Flooring Contractors · Beacon Flooring Contractors · Medway Flooring Contractors · Whitman Flooring Contractors