Plumbing Wall behind Stackable W/D: partial or full finish?

SparklingWater

11 years ago

Related Stories

MORE ROOMSBehind a Garage Door, a Family Fun Room

Designer Kerrie Kelly's secrets to this low-budget garage makeover: a soothing palette, horizontal stripes and dashes of color

Full Story

LAUNDRY ROOMSA Kitchen Laundry Cabinet Full of Surprises

A little DIY spirit allowed this homeowner to add a washer, dryer, kitchen countertop and dining table all in one

Full Story

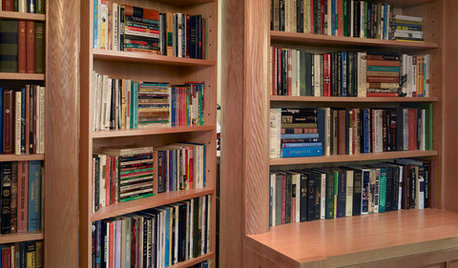

GREAT HOME PROJECTSHow to Create a Secret Doorway Behind a Bookcase

Hide your valuables (or unsightly necessities) in a room or nook that no one will guess is there

Full Story

CONTEMPORARY HOMESMy Houzz: Color and Fun Behind a Victorian Facade

Eclectic high-end and thrifty furnishings give a Toronto family’s traditional 1880s townhouse new flair

Full Story

HOUZZ TOURSMy Houzz: Home Full of Boys Achieves Order and Inspiration

A 3-month overhaul produces an organized and inviting space fit for this Florida family of 9

Full Story

BATHROOM MAKEOVERSRoom of the Day: Superstar Style for a Small Full Bathroom

Warm metals, a claw-foot tub, repurposed outdoor faucets and a special sink base contribute to this stellar renovation

Full Story

LIFE8 Ways to Make an Extra-Full Nest Work Happily

If multiple generations or extended family shares your home, these strategies can help you keep the peace

Full Story

SMALL HOMESCan You Live a Full Life in 220 Square Feet?

Adjusting mind-sets along with furniture may be the key to happiness for tiny-home dwellers

Full Story

HOUZZ TOURSHouzz Tour: From Summer Cottage to Full-Time Home

A retired NHL player and his family expand their former vacation home with a big addition and an interesting side-by-side design

Full Story

WOODDesign Workshop: Plywood as Finish

Trendproof your interior with this sensible guide to using this utilitarian material indoors

Full StoryMore Discussions

weedmeister

SparklingWaterOriginal Author

Related Professionals

Everett Kitchen & Bathroom Designers · Hillsboro Kitchen & Bathroom Designers · Palm Harbor Kitchen & Bathroom Designers · Pleasanton Kitchen & Bathroom Designers · South Farmingdale Kitchen & Bathroom Designers · North Arlington Kitchen & Bathroom Remodelers · Sicklerville Kitchen & Bathroom Remodelers · Southampton Kitchen & Bathroom Remodelers · Phillipsburg Kitchen & Bathroom Remodelers · Beaumont Custom Closet Designers · Lilburn Custom Closet Designers · Hastings Flooring Contractors · Oakdale Flooring Contractors · South Plainfield Flooring Contractors · Worcester Flooring ContractorsSparklingWaterOriginal Author