Clock Repair Class

jemdandy

10 years ago

Related Stories

FURNITUREMust-Know Furniture: The Grandfather Clock

This timeless classic is great for an entryway, an awkward corner, a bedroom and more. Learn how to make it work

Full Story

FURNITUREMust-Know Furniture: The Mora Clock

See if it’s the right time to make one of these 18th-century Gustavian glories part of your home

Full Story

KITCHEN DESIGNSchoolhouse Style Rocks in the Kitchen

Which class-y idea suits your kitchen best? a) a vintage clock; b) storage lockers; c) chalkboard counters; d) all of the above

Full Story

EVENTSDon't Throw Away Another Household Item Before Reading This

Repair Cafe events around the world enlist savvy volunteers to fix broken lamps, bicycles, electronics, small appliances, clothing and more

Full Story

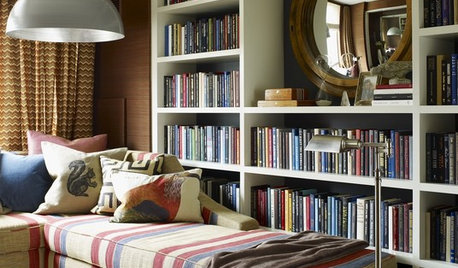

DECORATING GUIDESImpress Your Guests: 8 Tips for Gracious Guest Rooms

Offer concierge-style luxury on a bellhop's budget with these ideas to turn a spare bedroom into a first-class, guest-ready retreat

Full Story

ACCESSORIES8 Low-Cost Luxuries With a Big Payoff

Consider the small stuff — like switch plates and throw pillows — to give your home a touch of class

Full Story

DECORATING GUIDESWhat to Look for at the Flea Market Now

Find a Great Old Clock, Camera, Portrait, Chair or Globe and It's Your Lucky Day

Full Story

LIFEStressed Out? Try Hitting the Woodshop

Building things with your hands just might boost your mood while giving you personal new pieces for your home

Full Story

COFFEE WITH AN ARCHITECTWhat My Kids Have Taught Me About Working From Home

Candy and Legos aren't the only things certain small people have brought to my architecture business

Full StorySponsored

Your Industry Leading Flooring Refinishers & Installers in Columbus

socks

liz

Related Discussions

What is an all-blue Touch of Class?

Q

Right To Repair Act: Independent Shops Want Repair Codes

Q

Carrier Heat Exchanger Class Action Settlement

Q

Family heirlooms in the kitchen (or garage)?

Q

rhizo_1 (North AL) zone 7

jemdandyOriginal Author

rhizo_1 (North AL) zone 7

jemdandyOriginal Author

rhizo_1 (North AL) zone 7

jemdandyOriginal Author