Construction adhesive behind stainless steel backsplash a must???

mudworm

9 years ago

Related Stories

KITCHEN DESIGNKitchen Counters: Stainless Steel, the Chefs' Choice

Professional-grade strength and shining beauty unite in classic stainless steel countertops for the kitchen

Full Story

HOUSEKEEPINGHow to Clean Stainless Steel

Protect this popular kitchen material with a consistent but gentle cleaning routine

Full Story

KITCHEN COUNTERTOPS10 Great Backsplashes to Pair With Stainless Steel Counters

Simplify your decision-making with these ideas for materials that work well with stainless steel counters

Full Story

KITCHEN DESIGNKitchen Sinks: Stainless Steel Shines for Affordability and Strength

Look to a stainless steel sink for durability and sleek aesthetics at a budget-minded price

Full Story

KITCHEN DESIGNSo Over Stainless in the Kitchen? 14 Reasons to Give In to Color

Colorful kitchen appliances are popular again, and now you've got more choices than ever. Which would you choose?

Full Story

ARCHITECTUREDesign Workshop: Getting a Feel for Steel

Versatile and strong beyond belief, steel can create amazing expressions in homes and landscapes

Full Story

DECORATING GUIDES25 Design Trends Coming to Homes Near You in 2016

From black stainless steel appliances to outdoor fabrics used indoors, these design ideas will be gaining steam in the new year

Full Story

KITCHEN DESIGNKitchen of the Week: Industrial Design’s Softer Side

Dark gray cabinets and stainless steel mix with warm oak accents in a bright, family-friendly London kitchen

Full Story

KITCHEN CABINETSCabinets 101: How to Choose Construction, Materials and Style

Do you want custom, semicustom or stock cabinets? Frameless or framed construction? We review the options

Full Story

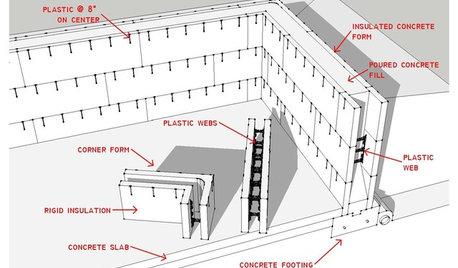

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

kudzu9

Joseph Corlett, LLC

Related Professionals

Fox Lake Kitchen & Bathroom Designers · Haslett Kitchen & Bathroom Designers · Rancho Mirage Kitchen & Bathroom Designers · Redmond Kitchen & Bathroom Designers · Sun City Kitchen & Bathroom Designers · Cloverly Kitchen & Bathroom Remodelers · Morgan Hill Kitchen & Bathroom Remodelers · Wilmington Kitchen & Bathroom Remodelers · Farmers Branch Cabinets & Cabinetry · Graham Cabinets & Cabinetry · Norfolk Cabinets & Cabinetry · Whitehall Cabinets & Cabinetry · Atascocita Cabinets & Cabinetry · Gardere Design-Build Firms · Shady Hills Design-Build FirmsBunny

practigal

mudwormOriginal Author

kudzu9

kudzu9

Bunny

Joseph Corlett, LLC

Joseph Corlett, LLC

cookncarpenter

Bunny

kudzu9

Joseph Corlett, LLC

HerrDoktorProfessor

mudwormOriginal Author

crcollins1_gw