Geeking out over cab construction

What can I say, I'm an engineer: electrical/computer, so they don't let me around sharp stuff, but that doesn't stop me from obsessing over stuff.

I've been trying to understand different build choices cabinet makers make and see who does what.

I've looked rather closely at Starmark, Dynasty, and local custom, looking at what I can see of construction.

The custom guy I talked to I could see everything in his shop. He uses pocket holes to build the face frames and to attach the frame to the box.

I've tried to look at Starmark and Dynasty, as much as you can on an installed display.

As far as I can tell, both actually staple/glue the face frame to the box. Does this sound right? Starmark uses a lot of staples, Dynasty relatively few, but they're still there. (At least if what I think is a staple is a staple ...)

Of course, this doesn't say how the face frames themselves are constructed. I'm not sure I can see this easily on installed cabs?

What is the upper end join for face frame to box?

I gotta admit, I liked talking the custom builder (and I have a couple of more meetings set with others, as well.) I've talked to a number of KDs and they all more or less picked a line and pushed it. Being an engineer, I want to know the tradeoffs. I want them to ask questions and then to explain how they picked a vendor based on my answers. When they just pitch one brand without explanation, I can't help but wonder if they're getting paid to push them.

I wonder if I'm a PITA as a customer ... but I'm just terribly curious about everything.

Comments (48)

katy-lou

10 years agolast modified: 9 years agoHa as one engineer to another, I so understand. Ours have been hand built largely in place. I can share blow by blow pics of the construction if you'd like. Boxes are constructed using actual joinery, face frames are mortised and tenon together and full length splines to the boxes. I have gotten the impression that this is somewhat unusual these days, but we have certainly appreciated the time, care and details that have gone ino their construction. And yeah we're also one of those that have had to understand the whys and hows of it all :)

jakuvall

10 years agolast modified: 9 years agoLong but not exhaustive and you asked...

Face frames- the most common method used by both semi custom and local "custom" builders is pocket hole construction. Since this is a butt joint, end grain to long grain, the strength comes from the screw. Glue is merely cosmetic, keeping the joint tight for finishing.Next step up- upper middle cabinets- usually manufactured not common in small shops but does exist- Is doweled frames- or loose tenons. Now you have long grain to long grain glue-very strong. From what I've seen doweled are better as the fit is often superior especially when it comes to mfg cabinets.

Top of the line is mortise and tenon-furniture quality, a joint to last generations. . Hi end manufactured and hi end local custom.( Probably more common in mfg)NOTe- many mfg tout mortise and tenon when referring to door construction. Read carefully. And in fact they are usually referring to cope and sile.

Face frame to carcass-

Pocket hole is more common in local custom often with thicker (3/4") sides which you need to make it work. Otherwise thicker is overkill. The issue with Pocket holes here (and on frames) is "compression set". As wood expands and contracts seasonally it presses aginst the steel. Eventually the wood fibers are damaged and it no longer expands making the screw loose.(This is why hammer heads fall off) Without a joint to stabilize it play is introduced.Some better local will use splines or biscuits as noted. IMO biscuits are better leaving the plywood slightly more stable. But the pros and cons of either could be argued forever.

Edited to correct this

Semi Custom Manufacturers almost all use staples BUT not all are equal. (After checking I notice that all but my mainstream brand do not use staples.)

Staples with a dado, industrial (urethane) hot glue are best.

A rabbet joint is a little down the scale.

Most importantly what glue, how much is used, and application are all critical. Glue up is the one reason I go om factory tours-i want to see how rushed they are. Even on sample "mini bases" _sed to show construction you can't tell.

What you can see .. Lots of staples is a bad sign

Moderate number, evenly spaced speaks -good.In the long run any of the methods described DONE WELL will produce a cabinet. Similarly an awful lot of "fuss" is palced on material. "- must have plywood". The material itself does not make or break the quality. Small shops hate particle because it is heavy and requires special methods and equipment to be properly fabricated. It is not inherently a poorer choice. Depends on what, and how. Besides just what is the ply you are being given. Show me the specs. (There are many variables in each)

Ultimately the single giggest factors are wood grading and selection and finish. That you CAN see. Look at some light or natural colored cabinets. Is the selection consistant? Grading? Feel the finish- feel the edges and back. Look it over.

Both of these are areas where mid size mfg's win. They get a full truck load of cherry and buy enough to be treated well. One brand I use sorts the lumber manually off the truck for a second grading. Sure I can go in and hand select boards at a supplier, but the pickings are not close.

Keeping a stable environment during production is expensive and beyond the scope of most small shops. Wood breathes and moves, it counts.

Finally finish. Fully catalyzed varnish is tougher than any other choice. All mfgs use it, few small shops. What is the wet build of the finish? Do they contol it? Almost every mfg has a rep from a finishing company that makes weekly visits and is on call.How do you, the consumer get to see this? If they keep mini bases around they can show you. Some places have sections of display to show you a little. In the end asking questions is the best way. Many (most) KD's won't know this stuff even if they went to training, just not the way they are put together (I'm a tad odd)

Are they just getting paid to push a brand- occasionally a larger mfg may have a spiff program. These typically coincide with an advertised special to the consumer. But most KD's will try to put you in the brand that: fits your budget, your wants and gives them the least headaches.

This post was edited by jakuvall on Fri, Nov 8, 13 at 12:57

Related Professionals

Buffalo Kitchen & Bathroom Designers · Flint Kitchen & Bathroom Designers · Fresno Kitchen & Bathroom Designers · Glens Falls Kitchen & Bathroom Designers · Martinsburg Kitchen & Bathroom Designers · Ossining Kitchen & Bathroom Designers · Calverton Kitchen & Bathroom Remodelers · Idaho Falls Kitchen & Bathroom Remodelers · Omaha Kitchen & Bathroom Remodelers · Salinas Kitchen & Bathroom Remodelers · Skokie Kitchen & Bathroom Remodelers · Bullhead City Cabinets & Cabinetry · Marco Island Cabinets & Cabinetry · Wyckoff Cabinets & Cabinetry · Baldwin Tile and Stone Contractorscookncarpenter

10 years agolast modified: 9 years agoAs a 62 year old finish carpenter who was taught by guys from the greatest generation, and as katy-lou implies, I sadly believe true craftsmanship is a becoming a lost art. Oh, they're still out there, but not easy to find. Good luck!

aptosca

Original Author10 years agolast modified: 9 years agokaty-lou: yeah, if you're an OCD engineer, gardenweb can be dangerous. I'm not totaling up the hours I've spent reading. It's been said many times before, but I'll say it again: who knew there was so much to kitchen cabinets. At first it seemed overwhelming. Now it's getting fun.

Where abouts are you? I'm guessing going as custom as you mention would be near impossible and (I'm guessing) blow my budget. I've heard of one guy in my area that might do something like that but his stuff is scary to the point of every piece being a work of art.

jakuvall: thanks for all the info! I wasn't going to specifically ask you but having read lots of other stuff you've written, I was kind of hoping.

I'm looking for inset cherry with a natural finish. That eliminates a few people (though honestly, I have trouble keeping them straight ... really gotta get this into a spreadsheet.)

On the brand front I've been pitched Dynasty, Medallion, Starmark, Columbia, and Dura Supreme. A couple of places carry Crystal but shy away from it. One place has Brookhaven, same story. Very few people have inset displays. I think I saw a Dynasty inset display w/o soft close and w/magnet stops which freaked me out a little.

Any comments? I think you've said in the past you carry Brookhaven. No sure what brand you use next step down? I just I remember you saying you passed on a few because they didn't fit a gap.

The first local shop I visited uses pocket screws on the face frame and frame to box. But he is probably bigger than the others I'll be visiting. We talked about wood selection and it seems like his volume gives you some of the opportunities you mentioned, to select. We talked about the panel, the tradeoff of plywood vs. solid, the choice of joined boards vs. symmetric veneers (which I kind of hate.)

I guess I'll bite the bullet and post my layouts (in a follow up).

Thanks everybody for the input!

jakuvall

10 years agolast modified: 9 years agoAptos-I handled BH where I used to work, not now on my own.

As construction goes with insets I like full sub tops.If your getting exposed hinges you won't find soft close at those price pts AFAIK, magnetic latches are the norm but a few are use a nicer metal one-uncommon. I only have SC on my hi-end, custom, M & T, has exposed with soft closethey use rare earth magnets imbedded in the doors and rails to accomplish that.

Since your after natural cherry I'd be asking about grade and selection and looking at samples and photos of real jobs. If doing a reverse solid wood how wide are the boards? What is your preference for variation?If veneer panel how well does it match and age. There is no single correct answer to that. For instance my hi end brand does heavy veneered panels that match well even with age, next brand down I lean toward solid.

I try to avoid reccommending specific brands here, just say who has what. For a client I can suggest between what I have, even direct them elsewhere. Any KD's knowledge of brands they don't currently carry is anecdotal.

I suggest shopping for the right person. The right KD- a good fit personally, responsive but willing to challenge, attentive, knows how to work the brand, resolves issues with the mfg and installer- makes a bigger difference in this kind of purchase than many of the details. Usually the right person that can match your budget brings a good choice for brand.

Your conducting a job interview more than a product search.

It Is more difficult to find, easier to recognize. Tip- most people are looking for "the reason NOT to buy" - look for reasons to hire.User

10 years agolast modified: 9 years agoConstruction is important, don't get me wrong. But, unless you're trying to win a contest from the fire department on the last cabinet to stand up to a fire axe, once you are in a certain dollar figure for cabinetry, what's more important is the wood chosen and finish quality. And the ability to customize the product. You're not paying all that $$ for boxes and construction. You're paying it for the pretty stuff that you see.

Finish quality and durability is where factory cabinets shine over local custom. There isn't a local maker who can ever achieve a finish as durable as a factory finish. Look up KCMA testing and see if any of the shops would let you do any of that on a test cabinet.

And the ability to customize, surprisingly, is also where some local "custom" makers fall down on the job. They simply build boxes and order doors. In limited woods, profiles, and sizes. That is NOT custom in anyone's mind, but it's what they call themselves.

A true custom maker or line should have the ability to let you choose whatever wood you want, whatever door profile you want, whatever outside edge, whatever inside edge, bead or no bead and any finish that you want, in whatever size you want. (For a price, to be sure!). If you are restricted to choosing a single style of shaker cabinet with no customization of any of that, then that's not custom.

I have a customer right now working on a pool house who wants a certain shade of Sherwin Williams blue for it, and who needs a 13 1/2" drawer base in it because we're cramming a lot of stuff in a very small space and every inch counts. It's not a problem at all in Dynasty. And it shouldn't be a problem with any other upper end semi custom line either. If I need something that's outside of Dynasty's guidelines, there's always Omega, which will dovetail with Dynasty to have the same finish and build characteristics and fit into the design like a glove.

I used that recently for an end panel to finish off a breakfast hutch. End panels usually have the decorative panels line up with the pantry cabinet door alignment, but I used Omega custom to have the decorative panels align with base cabinet (34 1/2") the space between the counter and upper (18") and the upper cabinet 39"). Then I had the rear paneled with a veneer, because it would show. No problem for any of that, and to get sprayed the same exact color as the rest of the order. And the job cost stayed low because I only needed that and one other custom piece.

That's what you are looking for in a cabinet line, and if I may say so, a designer. Someone who can design to your taste and budget. If you can find a KD who you click with, there are a LOT of cabinet lines that will meet the above criteria, so just let them suggest which of their lines they'd put you in. Once again, if you are at a certain dollar figure, you can get what you want in a lot of lines, and the line is less important than the designer.

A lot of people go about their project backwards in deciding on what line they must have from the specs, and then end up finding that they have difficulty working with the designer that works with that line.

So, go talk to some people in person. See who you can spend a lot of time with for the next 6 months or so and not kill. And who won't kill you. :)

jakuvall

10 years agolast modified: 9 years agoDitto to LWO

Signed on to add as far as specs when selecting brands for my businees only hard rules I had where- only Blum or Grass hardware and the ability to modify enough to design well, at every price point so I start at mid range. As price goes up I expect the spec to also.

I shopped for brands by hiring a company, not buying boxes. Turns out I also favor privately held brands over conglomerates but many factors involved in that.

aptosca

Original Author10 years agolast modified: 9 years agolive_wire_oak:

The "geeking out" part is not so much about saying one type of construction is better than another than it is about wanting to understand, being terribly curious. I kind of want to understand it all, not just the minimal I need for my kitchens.

I admit wood selection and finish seem important ... but it seems like it's hard to evaluate. I know the local guy i talked to yesterday does use conversion varnish. We talked about wood selection (he gets cherry in 5-8 in boards, if I recall.) He'd probably let me pick boards if I wanted to, but I'm not qualified. He in particular is definitely not the build boxes and buy doors and fit them in. At least in the part of his shop I saw he doesn't use a ton of cnc stuff. I saw some of his folks penciling out weird angles.

Another gentleman I talked to orders doors, so they may be another story. Haven't visited there yet.

(You did touch on end panels. The guy I talked to includes that all standard ... but it does remind me: am I the only one of the planet that thinks end panels that look like doors look a little odd? I don't think it's because I've hung around in cheap kitchens. It just seems so form over function: there's no function there, why is there form? I entirely admit I can be a little odd about these things.)

I definitely don't have any desire to set on a particular brand. I just like understanding them, understanding the tradeoffs. Unfortunately, I've yet to meet a KD that really clicks with my curiosity. I don't feel like the customer from hell but, then again, I don't sell kitchens, so what do I know.

aptosca

Original Author10 years agolast modified: 9 years agojakuvall:

I've been able to figure out most of the abbreviations but I got to admit, "full sub tops" stumps me.

I hadn't thought about the exposed hinges on inset. That makes perfect sense and I completely missed it: that would be an obvious reason for what I saw. Several people have mentioned adding non-functional faux exposed hinges. Exposed hinges don't really push my buttons. I'm not looking for that much (appearance of) authenticity.

As far as wood selection goes, I can understand it's important but doubt my ability to really evaluate how well someone does it. I know about grade in redwood fencing. Is it as simple as asking what grade they use? For what it's worth, I have some natural Stickley mission cherry pieces that I love. I'm not looking for furniture quality cabinets but I don't feel like I know what to expect with respect to grade. Fortunately, as far as the cherry goes, I'd rather have solid wood with imperfections than veneer. It's just a personal/quirky preference. That might also be why I care about construction: I love "real" joinery on principle. I (almost certainly) can't afford M&T but if it were a an up charge I could handle, I'd probably do it because I like the idea. That'd make me happy.

aptosca

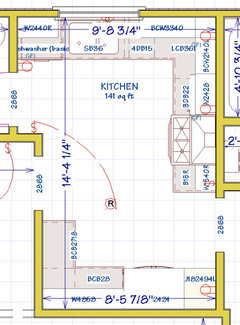

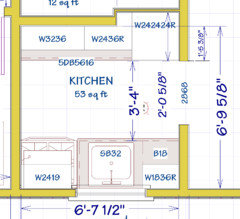

Original Author10 years agolast modified: 9 years agoCool: google docs and tgw actually make this easy:

House:

Cottage L:

Cottage U:

Cottage Galley:

meganmca

10 years agolast modified: 9 years agoYou do know about Cherry heartwood vs. sap wood (white-ish vs. red-ish) & stuff like that? With Cherry, it's not just about small knots, not having wavy grain (give it to me!), etc, it's about an actual color difference....if no one is picking the pieces, that is. It's not that it's "evil", but it's something to be aware of, for sure--the color variation isn't quite as obvious when they are raw, but after a few years of darkening, it's quite striking.

joaniepoanie

10 years agolast modified: 9 years agoDH is a mechanical engineer and even did some furniture building in his younger days and couldn't have given a rat's a%&s what cabinets I picked out! lol.... I did do my homework to get the most value for the $ and went with Dynasty....no regrets....am very happy with them. Just as a frame of reference....my 28 year old builder grade junk was still standing and functional until the day they were ripped out.

aptosca

Original Author10 years agolast modified: 9 years agomeganmca: I know enough to be dangerous. I know there's a difference but I don't really know what to expect. I know what my Stickley looks like but I'm not sure how much that will differ from kitchen cabs.

bookmom41

10 years agolast modified: 9 years agoaptos, I have cherry Fieldstone Cabinetry in my kitchen, which has been in for about a year. Fieldstone and Starmark are made by the same company and supposedly identical but marketed two different ways, or at least that's my understanding. Anyway, Fieldstone's website says the face frames are dadoed into the box. That said, I looked inside my cabinets and do see staples, too. FWIW, this cabinetry is beautiful and well-constructed but I also echo joaniepoanie; we ripped out 22 year old builder grade ugly fake oak and it was still structurally sound and functional.

katy-lou

10 years agolast modified: 9 years agoWe have geeked out at pretty much all of the process, we've been lucky to find someone to collaborate with us, and answer all of those questions. It has not been fast, or inexpensive, but all of those details have been important to us. Seeing the joinery in the drawers and doors, the finished holes (deburred, oiled, and brass inserts) for the shelf pegs, the matched grain, it makes me smile to see it. We also did natural cherry, participating in selecting and sourcing the A1 furniture grade ply for cases, and finding a specialty wood supplier (where it is already down selected multiple times, and then we hand selected lumber for individual components of the cabs). It is something to have seen it go from the raw lumber into panels or face frame etc. The costs have definitely been in the labor involved. Find someone you really can work well with. It is a long process and you are paying for their skills.

Gooster

10 years agolast modified: 9 years agoListen to the pros (the above) and your GC (if you've picked one). I'll add a few comments from a consumer perspective: you can get much more detailed literature if you really dig on the websites of the cabinet company -- or your KD can get them via the intranet portal. Nothing quite "datasheet worthy", but they usually have construction details. If you are getting inset in Cherry, you will need to get a very strong local maker. Many so called "custom" houses in NorCal simple can't do it properly or hate doing it, as you've probably found.

I'm surprised you said you were steered away from Crystal. I have Crystal cherry inset for my island. Two different GCs both approved of the line (the other said Decora was good as well). My KD said the precision was superior to their other lines. I considered Wellborn, Fieldcrest, Crystal and local custom. I did use full local "custom" for my family room, and I think the construction is overall inferior.

jakuvall

10 years agolast modified: 9 years agoaptos- "full sub tops" means the top of the cabinet has a full panel covering it- dadoed into the sides- it is completely covered. That's as opposed to corner blocks or side struts dadoed intot he sides goingfrom front to back.

grading- it's what you see that counts, you don't need to know wood. If you want to know about wood read Bruce Hoadley "Understanding Wood" but it's for geeks and wood workers only.

for cherry ask about sap wood- some, a little, can a door be replaced because of it. It is blond when new, turns grey with age.

mortise and tenon- not available as an upgrade from a mfg. Simpley should be one of many improvements as price goes up. It's "nice" certainly not necessary.

I don't see the point of fake exposed hinges but then I think soft close doors are overrated- great selling tool to distract from real quality issues- upgrade the hinge for a buck and oh my...

end panels and "Form follows function"- the phrase was coined by Louis Sullivan (Wright's mentor) and has been morped to mean other things. Take a look at their work. It does not mean "devoid of decoration or aeshetic options"

In the learn something new dept.- just noticed that two of the lines I carry have no staples at all so mispoke- will go and edit that.

bob_cville

10 years agolast modified: 9 years agoGiven the small space you have to work with, you should consider getting frameless cabinets. Especially for cabinets with drawers, the frameless option gives you more storage space.

Given a 15" wide cabinet and assuming 2" wide face frames, 3/4" wide cabinet sides for frameless, 1/2" wide drawer sides, and 1/2" wide side mounted full-extension drawer slides the inside width of a drawer would be 15 - 2 (0.75) - 2 (0.5) - 2 (0.5) == 11.5 inches with frameless vs. 15 - 2 ( 2) - 2 (0.5) - 2 (0.5) == 9 inches with a face frame cabinet

aptosca

Original Author10 years agolast modified: 9 years agogooster: Yeah, I've found inset to be somewhat uncommon. Few displays, among other things.

I group cabinet into those that do inset and those that don't. The first group I further group into those that should and those that shouldn't.

Still trying to figure out how to judge a maker's skill in that regard. Many don't have inset to show ....

jakuvall: for your lines that don't staple, can you tell how they're affixed?

bob_cville: Yeah, at some point I realized frameless is probably the best choice for the cottage. Just not enough space. Hoping not to do that in the house, though. That's where I get out of my league: how to allocate/size various cabs and their contents.

aptosca

Original Author10 years agolast modified: 9 years agobookmom41: I wonder if when you're gluing into a dado, the staples are there to hold the frame in place while the glue dries? Save having to clamp which would be harder to do on an assembly line? I don't know. The only thing I've seen that doesn't use staples is Crystal and I couldn't tell what they use. Not sure if the custom guys I talk to that use pocket holes from the cab to the frame dado as well.

jakuvall: I take your point on form over function. I even butchered it more because the real critique is when form degrades function, which isn't the case here.

I also am much more aware of the coloring differences between veneer and solid wood than I was. That virtually requires solid ends for natural cherry, I think?

The one thing I feel like I would like, though, is a simple face frame with a solid panel, rather than a face frame, a faux door frame, and then a solid panel. But nobody seems to do that ...

One KD I talked to yesterday noted that faux/non-functional exposed hinges could be considered recognition of/a hat tip to the past (as opposed to a cheap knockoff.) I hadn't thought of it that way. Having seen a nice Crystal display with functional exposed hinges, I'll have to think about going true.

I talked to another custom cab maker yesterday. Much smaller shop: just three guys. They do conversion varnish: the owner came into cabs via finish so emphasizes their finish. We talked about finish and he talked about painted requiring significantly more effort since light painted shows a lot more than natural/stained. They calk (I think that's what he said) the places where the door frame meets the panel so that there's no gap.

We talked about wood color and selection. He made me confident he spends a lot of time on that.

That said, he buys his doors from Cal Door, for better or for worse. I'm assuming the can't select color for them but at the same time, I assume he can reject them. Given how much time he spends on the door finish ...

Searching for 'cal door' on tgw has lead me to some other folks who have considered custom in my area ...

katy-lou

10 years agolast modified: 9 years agoIf you're in SoCal, you should look at Hile Studios in Altadena/Monrovia as well. In addition to furniture, they do custom cabs. Wasn't as much of an option for us since we're in CO, but something we definitely would have looked at more if we were closer.

aptosca

Original Author10 years agolast modified: 9 years agokaty-lou: I'm Northern CA (bay area) so out of JT Windows standard distribution area. Thanks, though.

Tim

10 years agolast modified: 9 years agoGet rid of any 'Designers' and go work directly with the custom cabinet maker.

I found a small custom cabinet maker and had full plywood construction cabinets done for less than even the mid-range stuff from Home Depot etc. The guy who makes the cabinets worked with me on the design and price. His partner who also makes the cabinets did the install - by himself.

If you're not talking directly to the person who is going to do the actual work, all you're doing is wasting money.

aptosca

Original Author10 years agolast modified: 9 years agoTorontoTim: I think this varies by area. As has been mentioned on gardenweb in the past, there aren't too many custom builders in the SF bay area. The cost of living is pretty high here which makes custom more costly than other areas (as far as I can tell).

Gooster

10 years agolast modified: 9 years agoaptos: There is a video on the Crystal site from an old Hometime that follows the construction from start to finish. They don't go into details, but you can see the dados routed in the face frames.

Here is a link that might be useful: Hometime Video

aptosca

Original Author10 years agolast modified: 9 years agogooster: Cool. It goes by pretty fast but (I think) I see clamps.

I'm still unsure if glued dados are all one needs to keep a face frame on? Or if stapled face frames are simply staples being used instead of clamps? Or, otherwise, why staples are needed. Or (finally) what folks that use pocket screwed-on face frames are doing. I can always ask the custom folks.

Thanks again, all. Feed the geek. :-)

bookmom41

10 years agolast modified: 9 years agoCool video. I didn't see the clamps, but also didn't notice any stapling going on. My father used to have a cabinet shop (restoration and reproduction, not modern kitchen cabinetry) so next time I talk to him, I'll see if he has any insight on the dado/staple thing. My guess is added stability but since I'm not a cabinetmaker, that guess isn't worth much.

This post was edited by bookmom41 on Sun, Nov 10, 13 at 20:41

aptosca

Original Author10 years agolast modified: 9 years agoI don't think Crystal uses staples. I felt around for them at a showroom on Saturday and couldn't find any.

So I guess the question is, once set, you don't need anything but dado and glue? They say in the video glue is stronger than wood.

I asked one custom maker who uses pocket holes and he says they glue but don't dado. So that trades the pocket hole screw for the dado. Don't know the implications of that ...

I did notice in the video them using some sort of nail to lock the tenon into the mortise. I've seen that on every cabinet I've looked at (since I've started looking for it). It's a little more noticeable in some than others but generally you have to look for it.

Not that I think that's a big deal, just made me appreciate the dowels that Stickley uses.

I saw a fairly elaborate Columbia setup on Saturday that had faux dowels. Were they real, they'd have locked the tenons in the mortise but these are just applied to the surface. Not only don't they go through the frame, they're not over the spot where the mortise/tenon meet. The actual M&T/C&S are locked with a nail like everyone else.

I've heard good things about Columbia but they don't do inset.

aptosca

Original Author10 years agolast modified: 9 years agoI'm making progress on a cab source. Have it down to a couple of custom and a couple of the national brands (but neither owned by a conglomerate ... not that that necessarily means anything.)

Every national rep says CA finishes aren't as good as non-CA finishes but the only concrete discussion about that (i.e., not FUD) refute the claim. All the local custom folks use catalyzed conv. varnish.

I'm looking at/reading more about exposed hinges. I gotta admit, they've become pretty compelling to me. To the extent I might not really care so much about soft close.

jakuvall, is the QCCI solution the one you pictured in the "soft close doors with exposed hinges on inset doors" thread (linked below)? I assume the magnet is the spot by the piston?

My first reaction is that any of the custom folks I've been talking to could handle this without too much difficulty. I'll have to ask them, of course. But I think it's something that at least one of them would be interested in using on other projects, too.

The magnets aren't too hard to find. Not sure if there's anything special about the plunger hardware.

Seems like they'd stay closed nicely without the click you get from magnet and metal physically meeting. I guess the plunger pressure might be fiddly.

I think mortised hinges would be a bigger challenge than the magnets. Not sure where I am on that yet.

Here is a link that might be useful: soft close doors with exposed hinges on inset doors

This post was edited by aptos_ca on Sat, Nov 16, 13 at 22:54

aptosca

Original Author10 years agolast modified: 9 years agoHmmm ... ran across the thread below. It has a little more raw data. Now I just have to interpret it, since finish could be a tie breaker.

I also have a quirky cabinet request (a cab in the kitchen that opens through the wall into the bath) that I'm not sure anyone but a local cab maker who came on site could do.

On the good side, I'm pretty sure I'll be happy with whatever I choose ...

Here is a link that might be useful: Factory Baked on Finish

User

10 years agolast modified: 9 years ago"I also have a quirky cabinet request (a cab in the kitchen that opens through the wall into the bath) "

Um, what's your reasoning behind that one?

You seriously want the sounds and smells of the bathroom to have a direct route into the kitchen? I don't think you've read enough threads from people who practically vomit at the thought of a powder room that opens off of the kitchen or dining room. I imagine a cabinet that's essentially a door into the bath would elicit the same regurgitation reflex. Bad juju for resale.

Also, you're overthinking the less important things here, and not giving enough importance to the vital things. Like the designer that you will need to work with. That's more important than most of the details. From mid grade on up, you are seriously not going to ever "wear out" kitchen cabinets, other than maybe nick the finish. (And that's why the finish is more important than a lot of the internal details.) People will be tired of their decor choices in them long before that ever happens.

aptosca

Original Author10 years agolast modified: 9 years agoSorry, I was not at all clear: there's a completely dead corner in the cottage kitchen. Instead of leaving it dead, I can put a cabinet there that opens through the wall into the bath. There's no opening for the cabinet (or, in fact, any view of the cabinet) in the kitchen.

I'm considering the designers. All the products I'm still considering are with people I think I can continue to build rapport with. I've spent a fair amount of time with each of them, much of which was for that purpose, to see how we worked together.

TB151

10 years agolast modified: 9 years agoSince you're geeking out I thought I would share a few pics I just recently took at my cabinetmaker's shop. He uses 3/4" all around for box construction, the drawers will be dovetail. His shop is incredible, he has a machine the size of a suburban and about 1000 molds to make infinite variations on moldings. This particular wood for mine is soft maple.

aptosca

Original Author10 years agolast modified: 9 years agoPretty.

Everybody I've talked to does 3/4" ply, dovetail solid sided drawers, etc. Some also have other options, but they all include the above.

The shops vary a fair amount. Smallest is three guys. Largest is ... 25? Most draw out and cut custom shapes. Other's have a fair amount of CNC equipment.

It's interesting to see and talk about.

aptosca

Original Author10 years agolast modified: 9 years agoLink from the horse's mouth on magnetic latches added.

Here is a link that might be useful: QCCI is pleased to announce its latest technological advancement, Earth Magnet.

ontariomom

10 years agolast modified: 9 years agoTorontoTim,

Can you please tell those us in your area what custom cabinet maker you used? Thanks,

Carol

aptosca

Original Author8 years agoHoly cow. November of 2013.

Anyway, I think I'm actually going to get to permits (at least submitted) next month. The city's not too bad on permits here, but summer, so who knows.

Plans are fairly completely and fairly completely different. Cottage was a non-starter for code so it's getting gutted.

My budget doubled. Twice. Waiting for the new heloc to close.

Anyway: question of the day is subtops. Stone is 3cm soapstone. Cabs are custom cherry inset.

Jakuvall, you mentioned full subtops for inset. For stability (of inset)? I'll have to talk to the cab maker and the stone guys.

Treb, any comment on the necessity, etc?

Noticed in the image they're not dadoed but planned for in the face frame so there's no reveal. I don't want a mitered edge. 3cm has a nice visual appeal to me.

Joseph Corlett, LLC

8 years ago3cm stone needs no subtop, just nice level cabinets on plane to each other.

jakuval

8 years agoSub tops have nothing to do with counters. They are a good way ( not the only way, maybe best) to prevent racking. Done well the flush to the bottom edge of the top rail preventing things in a drawer from getting stuck.

Joseph Corlett, LLC

8 years ago"Sub tops have nothing to do with counters."

It depends on the counter. Sub tops will void the warranty on solid surface. Sub tops are usually used on 2cm stone tops with a built-up front edge. The inset shown above to accommodate the sub top would have to be coordinated with the stone fabricator to get the right built-up edge depending on the doors and drawer fronts.

The best defense against racking is a competent installer.

aptosca

Original Author8 years agoInteresting (and thanks).

Most of what I've read said subtops for 2cm and none for 3cm. This issue was raised by a designer because she wanted to spec a mitered front. I'd guess that's because she does more 2cm than 3? In any case, I don't want a built-up edge. 3cm is just fine.

But while reading, I noted some people imply 2cm stone needs support from the subtop plywood. I wonder about that. I don't know enough about stone to know if it needs the support nor enough about plywood to know if it's effective in providing a meaningful amount.

Or is the subtop on 2cm because people will build up the edge on 2cm and that requires the subtop to raise the edge above drawer/doors etc?

I know jakuval has mentioned full subtops in the past. But all the way down at the drawer top? I'd never thought about that before. That would seem to have to be for stability only since it's way "sub" "top".

I am doing inset which is less forgiving of lack of true now and forever so ...

aptosca

Original Author8 years agoYeah, that's what I was envisioning. Thanks for the photo and comments.

Joseph Corlett, LLC

8 years ago" No bearing on counter, no affect on warranty."

I can promise you the pictured cabinet will void a solid surface warranty. Before I moved, I had the Corian manual with all the technical bulletins which specifically called for the removal of "dust covers" on cabinets because they retain heat. I can't find the bulletin online, but I requested a link from DuPont. When I get it, I will post it here.

aptosca thanked Joseph Corlett, LLCJoseph Corlett, LLC

8 years ago"But while reading, I noted some people imply 2cm stone needs support from the subtop plywood. I wonder about that. I don't know enough about stone to know if it needs the support nor enough about plywood to know if it's effective in providing a meaningful amount."

With the exception of fragile stones, full plywood underlayment is filler under 2cm stone and is unnecessary for support when the stone is properly installed on leveled cabinets. It is a waste of material as strip underlayment would work better in reducing the amount of dissimilar material contact. Try getting stone to lie flat on cheap CDX. See Chapter 3.

Check appliance specifications when using 2cm without a built-up edge. Sometimes the feet on a slide-in range won't go low enough to eliminate an unacceptably large gap between the stone top and the bottom of the cooktop flange.

Mitering stone edges is relatively expensive and should only be utilized on stones with lots of movement. A built-up edge on the right stone is more inconspicuous.

aptosca

Original Author8 years agoThanks for the comments and the link.

I'm getting 3cm soapstone. I don't want a built-up or mitered edge. 3cm is plenty thick for me. More, to me, looks too fat.

I'm pretty sure the cabinet maker is doing the install but he knows the GC well and they've worked with each other a lot so I figure they know how to work out those details.

But in any case, I'll be getting both of them specs on all the appliances. The DW is going to be paneled, the fridge integrated, and the sink a Shaw so the cab maker has lots of planning to do for all those uniqueness.

Thanks again.

jakuval