DIYer's, any tips on getting the cabinets perfectly level?

mudworm

11 years ago

Related Stories

MOST POPULARShe’s Baaack! See a Savvy DIYer’s Dramatic $400 Bathroom Makeover

You’ve already seen her dramatic laundry room makeover. Now check out super budget remodeler Ronda Batchelor’s stunning bathroom update

Full Story

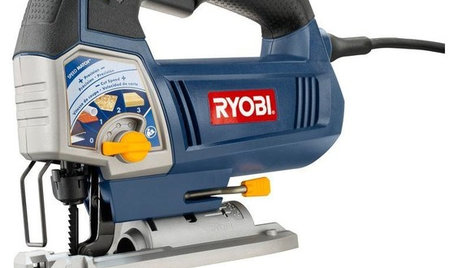

PRODUCT PICKSGuest Picks: Indispensable Tools for DIYers

Build your tool arsenal with these, and you’ll have the right equipment for any home project you take on

Full Story

MOST POPULAR12 Key Decorating Tips to Make Any Room Better

Get a great result even without an experienced touch by following these basic design guidelines

Full Story

LIFEReluctant DIYer’s Diary of a Dresser Makeover

Weekend project: Glossy new black-and-white dresser, hold the sandpaper

Full Story

BATHROOM DESIGN10 Top Tips for Getting Bathroom Tile Right

Good planning is essential for bathroom tile that's set properly and works with the rest of your renovation. These tips help you do it right

Full Story

DECORATING GUIDES5 Decorating Tips for Getting Scale Right

Know how to work art, sectionals, coffee tables, lamps and headboards for a positively perfect interior

Full Story

KITCHEN STORAGECabinets 101: How to Get the Storage You Want

Combine beauty and function in all of your cabinetry by keeping these basics in mind

Full Story

LIFE7 Tips to Get With a New Minimalist Mentality

Feeling overwhelmed by your stuff? Here's how to pare down, simplify and keep just what you need and love at home

Full Story

MOST POPULAR10 Tips for Organizing Your Closets and Cabinets

Add to the enjoyment of your home with these easy organizing strategies and containers — after you pare down, of course

Full Story

TRIMTrim Color Tips: Get Your White Trim Right

Set off wood tones, highlight architectural features, go minimalist ... white trim is anything but standard when you know how to use it

Full StorySponsored

Central Ohio's Trusted Home Remodeler Specializing in Kitchens & Baths

More Discussions

Donaleen Kohn

jakuvall

Related Professionals

Albany Kitchen & Bathroom Designers · Baltimore Kitchen & Bathroom Designers · Gainesville Kitchen & Bathroom Designers · Athens Kitchen & Bathroom Remodelers · Beaverton Kitchen & Bathroom Remodelers · Chester Kitchen & Bathroom Remodelers · Upper Saint Clair Kitchen & Bathroom Remodelers · West Palm Beach Kitchen & Bathroom Remodelers · Foster City Cabinets & Cabinetry · Indian Creek Cabinets & Cabinetry · Kentwood Cabinets & Cabinetry · Lakeside Cabinets & Cabinetry · Little Chute Cabinets & Cabinetry · Warr Acres Cabinets & Cabinetry · Dana Point Tile and Stone Contractorsangie_diy

sombreuil_mongrel

williamsem

jakuvall

jakuvall

snoonyb

ci_lantro

mudwormOriginal Author

CEFreeman

chiefneil

angie_diy

CEFreeman

mudwormOriginal Author

angie_diy