Can counters with "lines" work on an L?

kmmh

10 years ago

Related Stories

KITCHEN DESIGNWe Can Dream: 28 Kitchens With Breathtaking Views

In these homes, the best view in the house might just be from behind the kitchen counter

Full Story

MIDCENTURY HOMESHouzz Tour: How Can We Get Invited to This Awesome Midcentury Home?

A redwood-clad gem in California’s Marin County features a dreamy outdoor oasis with an open-door policy for the homeowners’ friends

Full Story

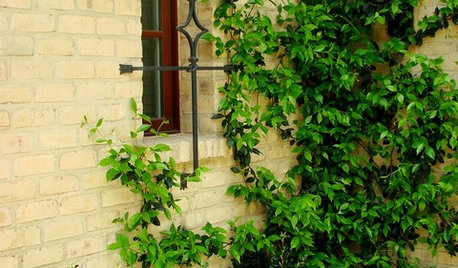

LIFEHow Your Landscaping Can Keep Burglars Away

Prevent home break-ins with strategic landscaping and good practices instead of menacing — and maybe less effective — measures

Full Story

KITCHEN DESIGNKitchen of the Week: Brick, Wood and Clean White Lines

A family kitchen retains its original brick but adds an eat-in area and bright new cabinets

Full Story

KITCHEN DESIGNTrending Now: 25 Kitchen Photos Houzzers Can’t Get Enough Of

Use the kitchens that have been added to the most ideabooks in the last few months to inspire your dream project

Full Story

HOUSEKEEPINGCan-Do Cleaning Strategies for Busy People

While you dream of having a maid (to go with the cook and chauffer), this simplified cleaning routine can keep your real-world home tidy

Full Story

CONTEMPORARY HOMESHouzz Tour: Strong, Modern Lines Stand Up to the Trees

Modernism takes kindly to the New York woods, with double-height ceilings for openness and a burbling creek for music

Full Story

FEEL-GOOD HOMEThe Question That Can Make You Love Your Home More

Change your relationship with your house for the better by focusing on the answer to something designers often ask

Full Story

PRODUCT PICKSGuest Picks: 19 Kitchen Upgrades for When You Can't Afford an Overhaul

Modernize an outdated kitchen with these accents and accessories until you get the renovation of your dreams

Full Story

KITCHEN DESIGNThe Cure for Houzz Envy: Kitchen Touches Anyone Can Do

Take your kitchen up a notch even if it will never reach top-of-the-line, with these cheap and easy decorating ideas

Full Story

sjhockeyfan325

RoRo67

Granite City Services

suzanne_sl

Cloud Swift

suzanne_sl

Cloud Swift

Cloud Swift

suzanne_sl