Help with basics of construction of White Cabinets

CT_Newbie

10 years ago

Related Stories

BATHROOM WORKBOOKStandard Fixture Dimensions and Measurements for a Primary Bath

Create a luxe bathroom that functions well with these key measurements and layout tips

Full Story

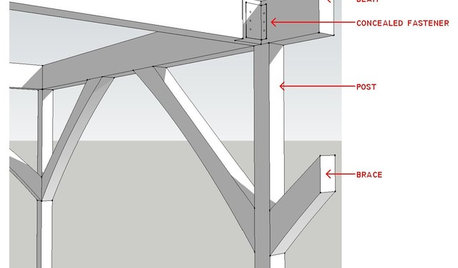

REMODELING GUIDESKnow Your House: Post and Beam Construction Basics

Learn about this simple, direct and elegant type of wood home construction that allows for generous personal expression

Full Story

DIY PROJECTSHelpful Hangers: French Cleats Support Projects Big and Small

From cabinets to birdhouses, French cleats hold projects securely in place

Full Story

KITCHEN CABINETSCabinets 101: How to Choose Construction, Materials and Style

Do you want custom, semicustom or stock cabinets? Frameless or framed construction? We review the options

Full Story

HOUZZ TOURSMy Houzz: A Basic Builder Home Gets the Glam Treatment

From blank canvas to decorated beauty, this home in Massachusetts changed a family's life in more ways than one

Full Story

BATHROOM DESIGNKey Measurements to Help You Design a Powder Room

Clearances, codes and coordination are critical in small spaces such as a powder room. Here’s what you should know

Full Story

HOME TECHTurn 'Obsolete' Tech Into Fun Home Help

Here's how to put your old Mac, Atari or Newton to work around the house

Full Story

KITCHEN DESIGNKey Measurements to Help You Design Your Kitchen

Get the ideal kitchen setup by understanding spatial relationships, building dimensions and work zones

Full Story

COLORPick-a-Paint Help: How to Create a Whole-House Color Palette

Don't be daunted. With these strategies, building a cohesive palette for your entire home is less difficult than it seems

Full StoryMore Discussions

nerdyshopper

jakuvall

Related Professionals

Carson Kitchen & Bathroom Designers · Ridgewood Kitchen & Bathroom Designers · Woodlawn Kitchen & Bathroom Designers · Adelphi Kitchen & Bathroom Remodelers · Buffalo Grove Kitchen & Bathroom Remodelers · League City Kitchen & Bathroom Remodelers · Sioux Falls Kitchen & Bathroom Remodelers · West Palm Beach Kitchen & Bathroom Remodelers · Dover Cabinets & Cabinetry · Gaffney Cabinets & Cabinetry · White Center Cabinets & Cabinetry · North Bay Shore Cabinets & Cabinetry · Bellwood Cabinets & Cabinetry · Davidson Tile and Stone Contractors · Suamico Design-Build Firmsbetter2boutside

CT_NewbieOriginal Author

allison0704