has anyone cut steel sheet metal before?

michoumonster

10 years ago

Related Stories

MUDROOMSThe Cure for Houzz Envy: Mudroom Touches Anyone Can Do

Make a utilitarian mudroom snazzier and better organized with these cheap and easy ideas

Full Story

LAUNDRY ROOMSThe Cure for Houzz Envy: Laundry Room Touches Anyone Can Do

Make fluffing and folding more enjoyable by borrowing these ideas from beautifully designed laundry rooms

Full Story

BUDGET DECORATINGThe Cure for Houzz Envy: Living Room Touches Anyone Can Do

Spiff up your living room with very little effort or expense, using ideas borrowed from covetable ones

Full Story

HOUZZ TVHouzz TV: This Dream Midcentury Home in a Forest Even Has Its Own Train

Original wood ceilings, a cool layout and, yes, a quarter-scale train persuaded these homeowners to take a chance on a run-down property

Full Story

KITCHEN DESIGNKitchen Sinks: Stainless Steel Shines for Affordability and Strength

Look to a stainless steel sink for durability and sleek aesthetics at a budget-minded price

Full Story

KIDS’ SPACESWho Says a Dining Room Has to Be a Dining Room?

Chucking the builder’s floor plan, a family reassigns rooms to work better for their needs

Full Story

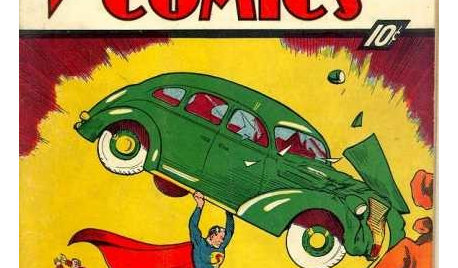

REMODELING GUIDESOne Guy Found a $175,000 Comic in His Wall. What Has Your Home Hidden?

Have you found a treasure, large or small, when remodeling your house? We want to see it!

Full Story

KITCHEN DESIGNThe Cure for Houzz Envy: Kitchen Touches Anyone Can Do

Take your kitchen up a notch even if it will never reach top-of-the-line, with these cheap and easy decorating ideas

Full Story

DECORATING GUIDESThe Cure for Houzz Envy: Guest Room Touches Anyone Can Do

Make overnight guests feel comfy and cozy with small, inexpensive niceties

Full Story

BEDROOMSThe Cure for Houzz Envy: Master Bedroom Touches Anyone Can Do

Make your bedroom a serene dream with easy moves that won’t give your bank account nightmares

Full Story

User

michoumonsterOriginal Author

Related Professionals

Barrington Hills Kitchen & Bathroom Designers · Bethpage Kitchen & Bathroom Designers · Yorba Linda Kitchen & Bathroom Designers · Waianae Kitchen & Bathroom Designers · Hopewell Kitchen & Bathroom Remodelers · Overland Park Kitchen & Bathroom Remodelers · Shawnee Kitchen & Bathroom Remodelers · South Park Township Kitchen & Bathroom Remodelers · Forest Hills Kitchen & Bathroom Remodelers · Sharonville Kitchen & Bathroom Remodelers · Salisbury Cabinets & Cabinetry · North Plainfield Cabinets & Cabinetry · Corsicana Tile and Stone Contractors · Scottdale Tile and Stone Contractors · Riverdale Design-Build FirmsHolly- Kay

wi-sailorgirl

brickeyee

wi-sailorgirl

brickeyee

michoumonsterOriginal Author

brickeyee

wi-sailorgirl

angie_diy

michoumonsterOriginal Author

sombreuil_mongrel

Russel_Matt

greenhaven