Hydronic 'enhancement'

apg4

11 years ago

Related Stories

SHOWERS5 Reasons to Choose a Walk-In Shower

Curbless and low-barrier showers can be accessible, low-maintenance and attractive

Full Story

TILE3 Key Steps for Grouting That Looks Its Best

Get your grout right to keep your tile beautiful and for an installation that will last

Full Story

FIREPLACESUpdated Woodstoves Keep Home Fires Burning

Better technology means more efficiency than ever for modern woodstoves

Full Story

MIDCENTURY HOMESHouzz Tour: An Eichler Remodel Spawns a Design Career

A homeowner finds her true calling upon redesigning her family's entire California home

Full Story

MODERN HOMESHouzz Tour: A Base Camp Designed for Adventure, Durability and Style

Rugged materials join refined good looks and clever details in a Washington family’s all-year getaway

Full Story

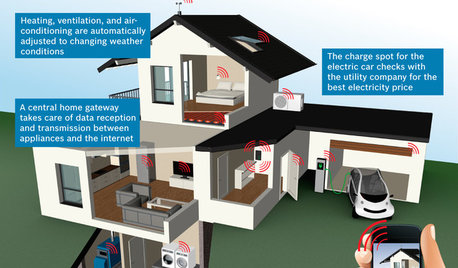

THE HARDWORKING HOMECES 2015: Inching Toward a Smarter Home

Companies are betting big on connected devices in 2015. Here’s a look at what’s to come

Full Story

GREEN BUILDINGMy Houzz: Sustainability Meets Global Style on an Australian Hilltop

It puts the power of the sun to work while keeping the budget in check and family socializing front and center

Full Story

FLOORSMake Your Floors Terrific With Terrazzo

Durable, sanitary and unique, this bespeckled surface is a winner for floors, walls, countertops and sinks

Full Story

ARCHITECTURERoots of Style: Midcentury Styles Respond to Modern Life

See how postwar lifestyles spawned a range of styles, including minimalist traditional, ranch, split level and modern shed. What's next?

Full Story

MATERIALSMaterials Workshop: Polycarbonate — a Low-Cost Alternative to Glass

Looking for something lighter, stronger and less expensive than glass? Multiwall polycarbonate may be a good option

Full Story

brickeyee

fsq4cw

Related Professionals

Brentwood Los Angeles Solar Energy Systems · Half Moon Bay Solar Energy Systems · Oakland Solar Energy Systems · Eden Prairie Solar Energy Systems · Franklin Solar Energy Systems · Broomfield Home Automation & Home Media · Chicago Home Automation & Home Media · Fort Lauderdale Home Automation & Home Media · Fox Chapel Home Automation & Home Media · Rosenberg Home Automation & Home Media · Tacoma Home Automation & Home Media · Tarpon Springs Home Automation & Home Media · Aurora Fireplaces · Palo Alto Fireplaces · Romeoville Fireplacesapg4Original Author