Leaking Furnace

shw001

17 years ago

Featured Answer

Comments (26)

bob_brown

17 years agomr_havac

17 years agoRelated Professionals

Half Moon Bay Solar Energy Systems · Riverside Solar Energy Systems · Moraga Solar Energy Systems · Easton Solar Energy Systems · Brentwood Home Automation & Home Media · Fayetteville Home Automation & Home Media · Miami Springs Home Automation & Home Media · Park Ridge Home Automation & Home Media · Roselle Home Automation & Home Media · Severn Home Automation & Home Media · Yeadon Home Automation & Home Media · Silver Spring Home Automation & Home Media · Lake Arrowhead Fireplaces · Romeoville Fireplaces · Winthrop Fireplacesshw001

17 years agomr_havac

17 years agoshw001

17 years agocasey_wa

17 years agoshw001

17 years agocasey_wa

17 years agoshw001

17 years agoshw001

17 years agomav411

17 years agokframe19

17 years agodglarsen

17 years agodglarsen

17 years agobk2000ext

17 years agojeffnette

17 years agomr_havac

17 years agodeepsnowutah

17 years agogsba

17 years agodglarsen

16 years agodglarsen

16 years agosudhs

16 years agoandrew99

15 years agogranddad314

10 years agoHU-573916085

3 years agolast modified: 3 years ago

Related Stories

HOUSEKEEPING12 Steps to a Safe, Cozy Home for a New Year

From smoke detectors to furnace filters, let January 1 be a reminder of some must-dos around the house

Full Story

HOUSEKEEPING5 Steps to Improve Your Heating System Now

Increase your heater's efficiency and safety for lower energy bills and greater peace of mind this winter

Full Story

DISASTER PREP & RECOVERYRemodeling After Water Damage: Tips From a Homeowner Who Did It

Learn the crucial steps and coping mechanisms that can help when flooding strikes your home

Full Story

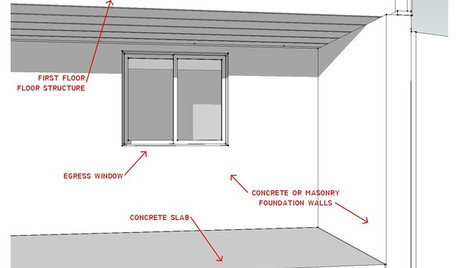

REMODELING GUIDESKnow Your House: The Steps in Finishing a Basement

Learn what it takes to finish a basement before you consider converting it into a playroom, office, guest room or gym

Full Story

REMODELING GUIDES7 Bad Things Your Home May Be Hiding

What you don't know about your home could cost you during a remodel. Here's what to plan for

Full Story

MOST POPULARA First-Time Buyer’s Guide to Home Maintenance

Take care of these tasks to avoid major home hassles, inefficiencies or unsightliness down the road

Full Story

DECORATING GUIDES10 Ways to Hide That Air Conditioner

Feeling boxed in designing around your mini-split air conditioner? Try one of these clever disguises and distractions

Full Story

REMODELING GUIDESThe Hidden Problems in Old Houses

Before snatching up an old home, get to know what you’re in for by understanding the potential horrors that lurk below the surface

Full Story

ARCHITECTURE15 Smart Design Choices for Cold Climates

Keep your home safe and comfortable in winter by choosing the right home features and systems

Full Story

GREEN BUILDING5 Common-Sense Ways to Get a Greener Home Design

You don't need fancy systems or elaborate schemes to make your home energy efficient and sustainable. You just need to choose wisely

Full Story

mr_havac