Has Puron proved itself reliable?

kailor

17 years ago

Related Stories

SMALL KITCHENSPersonal Spaces: Small-Kitchen Designs

In these kitchens, homeowners have found inventive ways to make the most of tight quarters

Full Story

MOST POPULARWhy We Love Midcentury Modern Design

There's a method to all this 'Mad Men'-ness — just look to psychology, tough times and, believe it or not, Apple

Full Story

GREEN BUILDINGHouzz Tour: See a Concrete House With a $0 Energy Bill

Passive House principles and universal design elements result in a home that’ll work efficiently for the long haul

Full Story

PETSThe Crate Conundrum: A Safe Place for Your Pooch

Get ideas for a comfy den for your dog that works well with your space too

Full Story

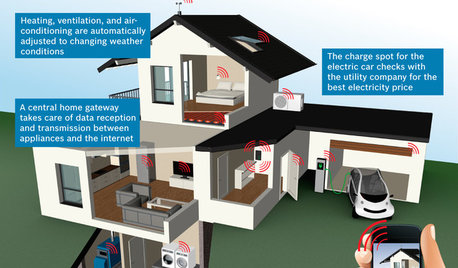

HOME TECHThe Future of Home Automation: Cheap, Wearable and Mobile!

Look for smart watches and glasses that can control your smart-phone apps, which in turn automate your home equipment

Full Story

KITCHEN DESIGNA Cook’s 6 Tips for Buying Kitchen Appliances

An avid home chef answers tricky questions about choosing the right oven, stovetop, vent hood and more

Full Story

GREEN BUILDINGWhy You Might Want to Build a House of Straw

Straw bales are cheap, easy to find and DIY-friendly. Get the basics on building with this renewable, ecofriendly material

Full Story

MOST POPULARMy Houzz: Open-Air Living in the Mountains of Bali

Community, jaw-dropping beauty and sustainability come together in a tropical paradise for a London expat

Full Story

CONTRACTOR TIPS10 Things to Discuss With Your Contractor Before Work Starts

Have a meeting a week before hammers and shovels fly to make sure everyone’s on the same page

Full Story

THE HARDWORKING HOMECES 2015: Inching Toward a Smarter Home

Companies are betting big on connected devices in 2015. Here’s a look at what’s to come

Full StoryMore Discussions

blacknumber1

bob_brown

Related Professionals

Lockhart Solar Energy Systems · Green Valley Solar Energy Systems · Imperial Beach Solar Energy Systems · Riverside Solar Energy Systems · Nutley Solar Energy Systems · New Lenox Solar Energy Systems · Chattanooga Home Automation & Home Media · Danville Home Automation & Home Media · Phoenix Home Automation & Home Media · Plainview Home Automation & Home Media · Severn Home Automation & Home Media · Wellesley Electricians · Germantown Fireplaces · Palos Hills Fireplaces · Simi Valley Fireplacesklabaach

blacknumber1

baymee

bama_dude

mr_havac

aemeeich_

bob_brown

pyropaul

baymee

dallasbill

bob_brown

pyropaul

bob_brown

blacknumber1

pyropaul

blacknumber1

davefr

dallasbill

hkky

aemeeich_

bob_brown

guyinacoldhouse

bob_brown

woodinvirginia

predfern