Dayton LP unit heater burner problem?

knick

15 years ago

Related Stories

GREAT HOME PROJECTSHow to Switch to a Tankless Water Heater

New project for a new year: Swap your conventional heater for an energy-saving model — and don’t be fooled by misinformation

Full Story

MOST POPULAR5 Ways to Hide That Big Air Conditioner in Your Yard

Don’t sweat that boxy A/C unit. Here’s how to place it out of sight and out of mind

Full Story

KITCHEN APPLIANCESFind the Right Oven Arrangement for Your Kitchen

Have all the options for ovens, with or without cooktops and drawers, left you steamed? This guide will help you simmer down

Full Story

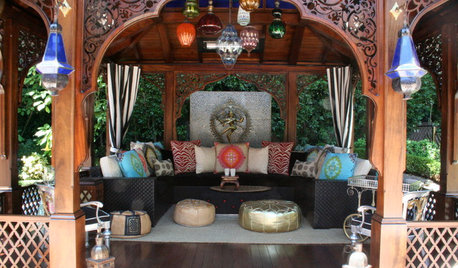

MOST POPULAR20 Outstanding Outdoor Living Rooms

Why give up style and comfort just because you add fresh air? Turn any porch or patio into a sumptuous room by following these leads

Full Story

ARCHITECTURE15 Smart Design Choices for Cold Climates

Keep your home safe and comfortable in winter by choosing the right home features and systems

Full Story

KITCHEN DESIGNHow to Choose the Right Hood Fan for Your Kitchen

Keep your kitchen clean and your home's air fresh by understanding all the options for ventilating via a hood fan

Full Story

DECORATING GUIDES10 Ways to Hide That Air Conditioner

Feeling boxed in designing around your mini-split air conditioner? Try one of these clever disguises and distractions

Full Story

LIFEHow to Prepare for and Live With a Power Outage

When electricity loss puts food, water and heat in jeopardy, don't be in the dark about how to stay as safe and comfortable as possible

Full Story

LIVING ROOMSHow to Convert Your Wood-Burning Fireplace

Learn about inserts and other options for switching your fireplace from wood to gas or electric

Full Story

HOUSEKEEPINGWhat's That Sound? 9 Home Noises and How to Fix Them

Bumps and thumps might be driving you crazy, but they also might mean big trouble. We give you the lowdown and which pro to call for help

Full Story

zl700

knickOriginal Author

Related Professionals

Richfield Solar Energy Systems · Irvington Solar Energy Systems · Verona Solar Energy Systems · Birmingham Home Automation & Home Media · Fayetteville Home Automation & Home Media · Fort Bragg Home Automation & Home Media · Herndon Home Automation & Home Media · Mount Lebanon Home Automation & Home Media · Park Ridge Home Automation & Home Media · Pittsburgh Home Automation & Home Media · Port Washington Home Automation & Home Media · Springfield Home Automation & Home Media · Silver Spring Home Automation & Home Media · Aurora Fireplaces · Leander Fireplaceszl700

knickOriginal Author

zl700

knickOriginal Author

kalining

ekgordon_charter_net