Oil burner is triggering motor reset button and won't start

tiffanys

13 years ago

Related Stories

HOME TECHBetter, Smarter Smoke Detectors Push All the Right Buttons

No more bashing in that smoke detector with a broomstick at 3 a.m. — if you haven't already yanked it out. Welcome the new, civilized breed

Full Story

FUN HOUZZ14 Things You Need to Start Doing Now for Your Spouse’s Sake

You have no idea how annoying your habits at home can be. We’re here to tell you

Full Story

DECLUTTERING5 Ways to Jump-Start a Whole-House Decluttering Effort

If the piles of paperwork and jampacked closets have you feeling like a deer in the headlights, take a deep breath and a baby step

Full Story

FUN HOUZZDon’t Be a Stickybeak — and Other Home-Related Lingo From Abroad

Need to hire a contractor or buy a certain piece of furniture in the U.K. or Australia? Keep this guide at hand

Full Story

GREAT HOME PROJECTSHow to Switch to a Tankless Water Heater

New project for a new year: Swap your conventional heater for an energy-saving model — and don’t be fooled by misinformation

Full Story

KITCHEN APPLIANCESLove to Cook? You Need a Fan. Find the Right Kind for You

Don't send budget dollars up in smoke when you need new kitchen ventilation. Here are 9 top types to consider

Full Story

REMODELING GUIDESGet the Look of a Built-in Fridge for Less

So you want a flush refrigerator but aren’t flush with funds. We’ve got just the workaround for you

Full Story

LIFEGet the Scoop on High-Design Litter Boxes

Unavoidable doesn't have to mean unpleasant; cats and guardians alike will purr over these terrific design solutions for the litter box

Full Story

KITCHEN DESIGNKitchen of the Week: Pushing Boundaries in a San Francisco Victorian

If the roll-up garage door doesn’t clue you in, the blue cabinets and oversize molding will: This kitchen is no ordinary Victorian galley

Full Story

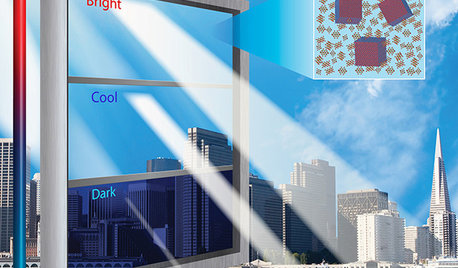

HOME TECHIs It Curtains for Curtains? Smart Glass Eliminates Window Coverings

Windows can now control light and heat through electricity and high-tech formulations, making blinds and shades optional

Full StorySponsored

Columbus Design-Build, Kitchen & Bath Remodeling, Historic Renovations

More Discussions

baymee

tiffanysOriginal Author

Related Professionals

Menifee Solar Energy Systems · Woodland Hills Solar Energy Systems · Saratoga Solar Energy Systems · Evanston Home Automation & Home Media · Fayetteville Home Automation & Home Media · Poway Home Automation & Home Media · South San Francisco Home Automation & Home Media · St. Louis Home Automation & Home Media · East Cleveland Home Automation & Home Media · Burlingame Electricians · Grafton Electricians · Hoffman Estates Fireplaces · Lone Tree Fireplaces · Oak Hill Fireplaces · Seaside Fireplacesbaymee

dapoppa

bus_driver

dapoppa

tiffanysOriginal Author

bus_driver

baymee

tiffanysOriginal Author

tiffanysOriginal Author

baymee

tiffanysOriginal Author

bus_driver