Best way to insulate between studs with rigid foam

gabb

14 years ago

Featured Answer

Comments (11)

jake2007

14 years agogabb

14 years agoRelated Professionals

Downers Grove Solar Energy Systems · Emeryville Solar Energy Systems · Phoenix Solar Energy Systems · Rialto Solar Energy Systems · Columbia Home Automation & Home Media · Park Ridge Home Automation & Home Media · Pittsburgh Home Automation & Home Media · Plantation Home Automation & Home Media · Tamiami Home Automation & Home Media · Winchester Home Automation & Home Media · Farmington Fireplaces · Hockessin Fireplaces · Hoffman Estates Fireplaces · Rockville Fireplaces · Crestwood Fireplacesnerdyshopper

14 years agogabb

14 years agoenergy_rater_la

14 years agogabb

14 years agogabb

14 years agoenergy_rater_la

14 years agogabb

14 years agoenergy_rater_la

14 years ago

Related Stories

MATERIALSInsulation Basics: What to Know About Spray Foam

Learn what exactly spray foam is, the pros and cons of using it and why you shouldn’t mess around with installation

Full Story

WINDOW TREATMENTSEasy Green: 9 Low-Cost Ways to Insulate Windows and Doors

Block drafts to boost both warmth and energy savings with these inexpensive but effective insulating strategies

Full Story

GREEN BUILDINGInsulation Basics: Heat, R-Value and the Building Envelope

Learn how heat moves through a home and the materials that can stop it, to make sure your insulation is as effective as you think

Full Story

GREEN BUILDINGInsulation Basics: Designing for Temperature Extremes in Any Season

Stay comfy during unpredictable weather — and prevent unexpected bills — by efficiently insulating and shading your home

Full Story

REMODELING GUIDESCool Your House (and Costs) With the Right Insulation

Insulation offers one of the best paybacks on your investment in your house. Here are some types to discuss with your contractor

Full Story

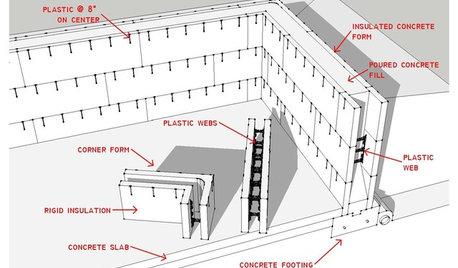

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

GREEN BUILDINGInsulation Basics: Natural and Recycled Materials

Consider sheep’s wool, denim, cork, cellulose and more for an ecofriendly insulation choice

Full Story

GREEN BUILDING5 Common-Sense Ways to Get a Greener Home Design

You don't need fancy systems or elaborate schemes to make your home energy efficient and sustainable. You just need to choose wisely

Full Story

REMODELING GUIDESContractor Tips: Finish Your Basement the Right Way

Go underground for the great room your home has been missing. Just make sure you consider these elements of finished basement design

Full Story

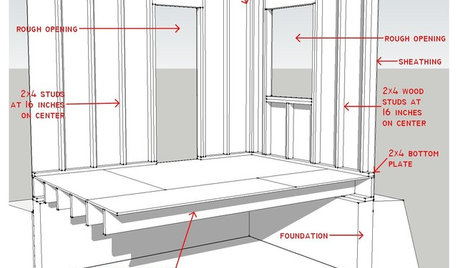

REMODELING GUIDESKnow Your House: Components of Efficient Walls

Learn about studs, rough openings and more in traditional platform-frame exterior walls

Full Story

energy_rater_la