AC not cooling well

Perman

11 years ago

Related Stories

LIFE6 Ways to Cool Off Without Air Conditioning

These methods can reduce temperatures in the home and save on energy bills

Full Story

GARDENING AND LANDSCAPINGChill Out: 10 Cool Ways to Beat the Heat Outdoors

Step away from the A/C's artificial blast — and treat yourself to these more natural cool-down methods in the great outdoors

Full Story

Guest Picks: We'll Drink to These!

Keep favorite summer drinks cold and at the ready with stylish holders and dispensers that are easy to take outside

Full Story

GARDENING AND LANDSCAPINGThe Allure of a Well-Designed Carport

Easy access, unobstructed views and architectural appeal are a few of the reasons to love a carport

Full Story

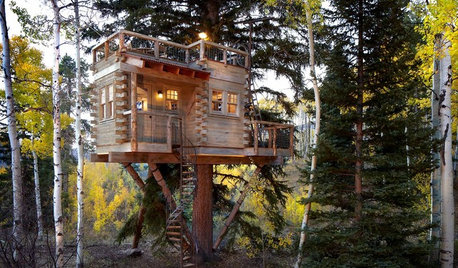

TREE HOUSESHouzz Call: Show Us Your Well-Designed Treehouse or Tree Fort!

Got a great treehouse or tree fort? We want to see it! Post yours in the Comments and we’ll feature the best in a future article

Full Story

KITCHEN DESIGN7 Strategies for a Well-Designed Kitchen

Get a kitchen that fits your lifestyle and your design tastes with these guidelines from an architect

Full Story

KITCHEN DESIGNCreate Your Own Checklist for a Well-Stocked Kitchen

Personalize the kitchen with your own must-haves from our list of top cooking tools, small appliances, pots, pans and more

Full Story

GARDENING GUIDESHow to Keep Your Citrus Trees Well Fed and Healthy

Ripe for some citrus fertilizer know-how? This mini guide will help your lemon, orange and grapefruit trees flourish

Full Story

ANTIQUESRoom of the Day: A Well-Worn Look for a Brand-New Home

Forays into antiques markets and online auctions bring old-time flavor to a sleek and soaring living-dining space

Full Story

KITCHEN OF THE WEEKKitchen of the Week: Good Flow for a Well-Detailed Chicago Kitchen

A smart floor plan and a timeless look create an inviting kitchen in a narrow space for a newly married couple

Full StorySponsored

Central Ohio's Trusted Home Remodeler Specializing in Kitchens & Baths

More Discussions

tima9209

clocert

Related Professionals

Attleboro Solar Energy Systems · Chatsworth Solar Energy Systems · Holliston Solar Energy Systems · Muscatine Solar Energy Systems · Teaneck Solar Energy Systems · Voorhees Solar Energy Systems · Yucca Valley Solar Energy Systems · Saratoga Solar Energy Systems · Gages Lake Home Automation & Home Media · Milton Home Automation & Home Media · Olathe Home Automation & Home Media · Weymouth Home Automation & Home Media · Channelview Fireplaces · Leander Fireplaces · Parkland Fireplaces