Steam Radiators - regulating

grannabelle

16 years ago

Related Stories

DECORATING GUIDESHow to Make Peace With Your Radiator

Turn a bulky, unattractive old heater into an appealing part of a room

Full Story

DECORATING GUIDESRadiator Covers Like You’ve Never Seen

From custom to DIY, these 10 ideas will help the radiator blend in, become a storage standout or both

Full Story

HOUZZ TOURSMy Houzz: Goodwill and Good Taste in a Grand Colonial

Welcoming the community for charity fundraisers and more, this Massachusetts home radiates graciousness

Full Story

BEDROOMS8 Steps to a Greener, More Peaceful Bedroom

Clear away clutter, clean the air and make over your bedding for an oasis that radiates calm and well-being

Full Story

REMODELING GUIDESClean-Burning Woodstoves Ignite a Greener Heating Trend

No need to rely on oil or gas to heat your home — new woodstove designs burn cleanly and are beautiful to boot

Full Story

FIREPLACESUpdated Woodstoves Keep Home Fires Burning

Better technology means more efficiency than ever for modern woodstoves

Full Story

HOUZZ TOURSHouzz Tour: Clever Storage Ideas From a Manhattan Duplex

A bookcase on tracks, wall-spanning storage, a Murphy bed and more give a comedy writer flexibility for working and living at home

Full Story

SMALL HOMESHouzz Tour: A Studio Makes the Most of Every Inch

Thoughtful design transforms a neglected London flat into a stylish multitasking home

Full Story

KITCHEN APPLIANCESFind the Right Cooktop for Your Kitchen

For a kitchen setup with sizzle, deciding between gas and electric is only the first hurdle. This guide can help

Full Story

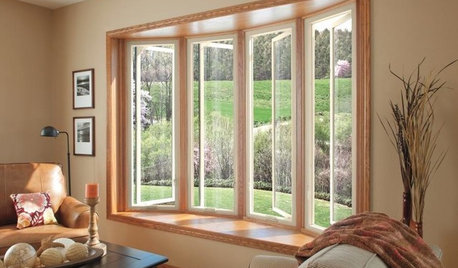

GREAT HOME PROJECTSUpgrade Your Windows for Beauty, Comfort and Big Energy Savings

Bid drafts or stuffiness farewell and say hello to lower utility bills with new, energy-efficient windows

Full StorySponsored

Columbus Area's Luxury Design Build Firm | 17x Best of Houzz Winner!

More Discussions

kframe19

grannabelleOriginal Author

Related Professionals

Little Ferry Solar Energy Systems · Muscatine Solar Energy Systems · South Whittier Home Automation & Home Media · Clearwater Home Automation & Home Media · Fayetteville Home Automation & Home Media · Goulds Home Automation & Home Media · Hanover Home Automation & Home Media · Odenton Home Automation & Home Media · Rowland Heights Home Automation & Home Media · Safety Harbor Home Automation & Home Media · San Mateo Home Automation & Home Media · East Setauket Home Automation & Home Media · Columbine Fireplaces · Crystal Lake Fireplaces · Evans Fireplaceskframe19

dchhat007

kframe19

kframe19

corvetteguy

kframe19

dchhat007

kframe19

kframe19

dchhat007

dchhat007

kframe19

dchhat007

kframe19

dchhat007

kframe19

dchhat007

kframe19

kframe19

dchhat007

dchhat007

dchhat007

kframe19

tmajor

kframe19

dchhat007

fourhappycampers

fourhappycampers

kframe19

kframe19

dchhat007

kframe19

fourhappycampers

kframe19