Proper spacing of pvc piping from furnace

taracol

10 years ago

Featured Answer

Comments (20)

mike_home

10 years agotaracol

10 years agoRelated Professionals

East Lake Solar Energy Systems · Lynn Solar Energy Systems · Randolph Solar Energy Systems · Bozeman Home Automation & Home Media · Campbell Home Automation & Home Media · Columbia Home Automation & Home Media · Cypress Home Automation & Home Media · Laurel Home Automation & Home Media · Mount Lebanon Home Automation & Home Media · Scottsdale Home Automation & Home Media · Southlake Home Automation & Home Media · St. Johns Home Automation & Home Media · Temecula Home Automation & Home Media · Oak Lawn Fireplaces · Simi Valley Fireplacesmike_home

10 years agotaracol

10 years agotaracol

10 years agomike_home

10 years agobus_driver

10 years agomike_home

10 years agotaracol

10 years agobrickeyee

10 years agoTinmantu

10 years agocountryboymo

10 years agomike_home

10 years agotaracol

10 years agomike_home

10 years agotaracol

10 years agotaracol

10 years agofelizabeth

2 years agomike_home

2 years ago

Related Stories

DECORATING GUIDESDIY: PVC Pipe Wine Holder

Rachelle Falcon shows how to make a spiffy modern wine holder with stuff from the hardware store

Full Story

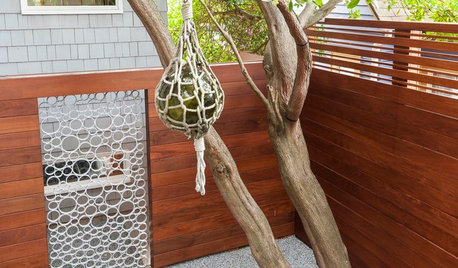

FENCES AND GATESA Designer Uses PVC Pipe to Cast a Modern Garden Gate

Landscape designer Scot Eckley walks us through the process of creating a custom aluminum ring gate

Full Story

KITCHEN DESIGNKitchen Recipes: Factory Cart Inspires a Dream Cooking Space

These homeowners' kitchen was almost nonexistent, so they whipped it up from scratch. See what they cook there and get the recipe too

Full Story

BATHROOM DESIGNWater Damage Spawns a Space-Saving Bathroom Remodel

A game of inches saved this small New York City bathroom from becoming too cramped and limited

Full Story

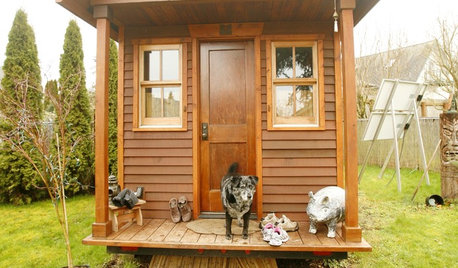

SMALL SPACESLife Lessons From 10 Years of Living in 84 Square Feet

Dee Williams was looking for a richer life. She found it by moving into a very tiny house

Full Story

BEFORE AND AFTERSA Boston Kitchen and Bath Go From Dreary to Darling

See how a $25,000 renovation budget gave 2 outdated spaces in a small Massachusetts apartment a brand-new look

Full Story

PETSWe Want to See the Most Creative Pet Spaces in the World

Houzz is seeking pet-friendly designs from around the globe. Get out your camera and post your photos now!

Full Story

INSIDE HOUZZSee a Couple’s New Spa-Like Bathroom From Lowe’s and Houzz

The sweepstake winners’ master bathroom gets a makeover with a new shower, tile and storage space

Full Story

DECORATING GUIDESWorld of Design: Decorating Ideas From 10 Renters Around the Globe

Even if you don’t own your home, you can live beautifully. Browse these ideas from international tenants who’ve made their spaces special

Full Story

KIDS’ SPACESTop Bunks: 15 Favorites From the Most Popular Kids’ Rooms in 2016

See the many creative designs for children’s bunk beds in photos popular with Houzz readers this year

Full StoryMore Discussions

mike_home