How to quiet some noisy circulator pumps

ellessebee

11 years ago

Featured Answer

Sort by:Oldest

Comments (10)

fsq4cw

11 years agoellessebee

11 years agoRelated Professionals

Phoenix Solar Energy Systems · Alafaya Solar Energy Systems · Elizabeth Solar Energy Systems · Moorpark Solar Energy Systems · Pacific Grove Solar Energy Systems · Ramsey Solar Energy Systems · Richfield Solar Energy Systems · Inver Grove Heights Solar Energy Systems · Lincolnwood Home Automation & Home Media · Port Washington Home Automation & Home Media · Valle Vista Home Automation & Home Media · Waltham Home Automation & Home Media · Westminster Home Automation & Home Media · Wilmington Home Automation & Home Media · Delhi Electriciansfsq4cw

11 years agogeoffrey_b

11 years agoionized_gw

11 years agogeoffrey_b

11 years agoellessebee

10 years agofsq4cw

10 years agoionized_gw

10 years ago

Related Stories

LANDSCAPE DESIGNDesign Your Landscape for Peace and Quiet

Block unwanted noise with plantings, barriers and water features for a more soothing outdoor experience

Full Story

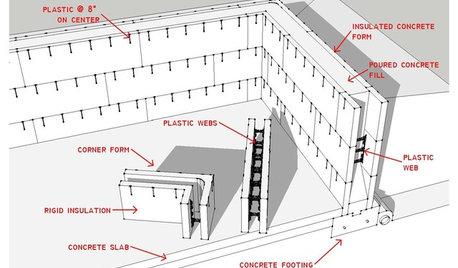

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

LAUNDRY ROOMSDouble-Duty Savvy: 10 Supersmart Laundry Room Combos

Throw some extra function in along with the fabric softener to spin your laundry room into mutitasking mode

Full Story

LANDSCAPE DESIGNGet Along With Less Lawn — Ideas to Save Water and Effort

Ditch the mower and lower your water bill while creating a feast for the eyes with diverse plantings and gathering places

Full Story

MATERIALSThe Most Popular Roofing Material is Affordable and Easy to Install

Asphalt shingles, the most widely used roof material in the U.S. are reliable and efficient, and may be right for you

Full Story

LANDSCAPE DESIGNCreate a Remarkable Garden by Thinking in 3D

Thinking of your space as a dimensional piece of sculpture can make it grand no matter what size it is

Full Story

BATHROOM DESIGNDreaming of a Spa Tub at Home? Read This Pro Advice First

Before you float away on visions of jets and bubbles and the steamiest water around, consider these very real spa tub issues

Full Story

MOST POPULARIs Open-Plan Living a Fad, or Here to Stay?

Architects, designers and Houzzers around the world have their say on this trend and predict how our homes might evolve

Full Story

KITCHEN DESIGNHave Your Open Kitchen and Close It Off Too

Get the best of both worlds with a kitchen that can hide or be in plain sight, thanks to doors, curtains and savvy design

Full Story

GREAT HOME PROJECTSHow to Add a Radiant Heat System

Enjoy comfy, consistent temperatures and maybe even energy savings with hydronic heating and cooling

Full StoryMore Discussions

Dmitry Brant