Negative House Pressure

taverty

11 years ago

Related Stories

GARDENING AND LANDSCAPINGGarden Design Essentials: Positive-Negative Space

Discover how to place your garden forms for visual balance and eye-pleasing pattern in the landscape

Full Story

HOUSEKEEPINGHow to Wash Your House

Avoid damage to siding and plants while getting your home's exterior shining clean, with this guide to using pressure washers and hoses

Full Story

HEALTHY HOMEHow to Choose a Home Water Filtering System

Learn which water purification method is best for your house, from pitchers to whole-house setups

Full Story

HOLIDAYSSet the Scene for a Stress-Free Holiday Visit

Put your guests at ease and take the pressure off hosting by prepping your space with psychology in mind

Full Story

DECORATING GUIDES12 Decorating Scenarios When You Should Do Nothing at All

By embracing the positives of negative space, you can strategically highlight key furnishings, give the eye a rest and create focal points

Full Story

LIGHTINGWhy It’s High Time to Reconsider Flush-Mount Lights

Look past your negative perceptions and see how versatile these lights can be

Full Story

MOST POPULARHouzz Tour: Going Off the Grid in 140 Square Feet

WIth $40,000 and a vision of living more simply, a California designer builds her ‘forever’ home — a tiny house on wheels

Full Story

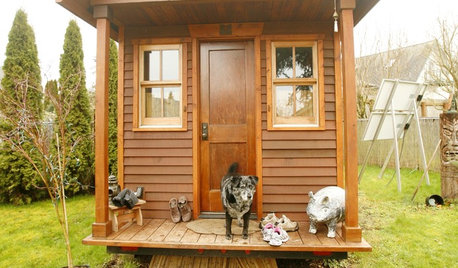

SMALL SPACESLife Lessons From 10 Years of Living in 84 Square Feet

Dee Williams was looking for a richer life. She found it by moving into a very tiny house

Full Story

MATERIALSInsulation Basics: What to Know About Spray Foam

Learn what exactly spray foam is, the pros and cons of using it and why you shouldn’t mess around with installation

Full Story

SMALL SPACESTiny Huts, Cabins and Modular Houses for Remote Living

City living got you down? Take shelter in the countryside in one of these latest designs fit for out-of-the-way living

Full Story

mike_home

energy_rater_la

Related Professionals

Beverly Hills Solar Energy Systems · Elmhurst Solar Energy Systems · Sanger Solar Energy Systems · Shelton Solar Energy Systems · Easton Solar Energy Systems · Castle Rock Home Automation & Home Media · Chattanooga Home Automation & Home Media · Coronado Home Automation & Home Media · Framingham Center Home Automation & Home Media · Medford Home Automation & Home Media · Richardson Home Automation & Home Media · San Jose Home Automation & Home Media · St. Johns Home Automation & Home Media · Layton Fireplaces · Santa Maria FireplacestavertyOriginal Author

mike_home

tavertyOriginal Author

weedmeister

tavertyOriginal Author

SaltiDawg

mike_home

tavertyOriginal Author

energy_rater_la

energy_rater_la

tavertyOriginal Author

energy_rater_la

tavertyOriginal Author

energy_rater_la

energy_rater_la

southerncanuck

energy_rater_la

countryboymo

energy_rater_la

countryboymo