Casco Bay Leather Sofa

chouipatsi

11 years ago

Related Stories

DESIGNER SHOWCASESSee the Daring Designs at the 2013 Kip's Bay Decorator Show House

New York designers show their latest creations in a fashion show for the home

Full Story

HOUZZ TOURSMy Houzz: Metropolitan Chic in Boston's Tony Back Bay

A 1928 penthouse apartment with river views gets elegant updates that nod to the past

Full Story

DESIGNER SHOWCASESGlamour and Colors Rule at 2016 Kips Bay Decorator Show House

See how 21 designers from around the U.S. outfitted a 1940 townhouse with vivid wall treatments and edgy furnishings

Full Story

EVENTSColors and Patterns Wow at the 2015 Kips Bay Decorator Show House

Go on a virtual tour as 22 designers put on a beautiful interior fashion show in NYC’s Arthur Sachs mansion

Full Story

DECORATING GUIDESRooms Delight at 2012 Kips Bay Decorator Show House

Bewitching colors and high-end touches wowed in Apartment 2102 of this year's showcase on Manhattan's Upper West Side

Full Story

FURNITUREHow to Buy a Quality Sofa That Will Last

Learn about foam versus feathers, seat depth, springs, fabric and more for a couch that will work for years to come

Full Story

FURNITUREWhy It's OK to Hate Your New Custom Sofa

It takes time to get used to bold new furniture, but dry your tears — the shock can be good for you. Here's what to expect

Full Story

PRODUCT PICKSGuest Picks: A Sofa Bed for Every Style

Make room for visiting friends and family with a sleeper sofa that converts in a pinch and fits your home's look

Full Story

SHOP HOUZZShop Houzz: Sofas for Every Style

Go for a couch that suits your interior design and your personality. With these curated picks, you’re bound to find a pleasing seat

Full Story

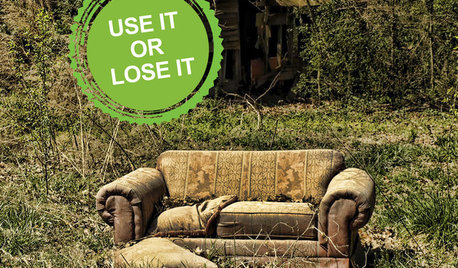

DECORATING GUIDESLose It: How to Reuse, Recycle or Replace Your Sofa

Follow these tips and tricks to keep your worn-out couch from ending up in a landfill

Full Story

iCustomSofa

iCustomSofa

Related Professionals

Augusta Furniture & Accessories · Beverly Hills Furniture & Accessories · Carson Furniture & Accessories · Miami Springs Carpenters · Norwood Carpenters · Temple Carpenters · Windsor Carpenters · Glendale Heights Cabinets & Cabinetry · Hammond Cabinets & Cabinetry · Watauga Cabinets & Cabinetry · Chandler Custom Closet Designers · Medway Custom Closet Designers · Crestview Interior Designers & Decorators · Rockland Interior Designers & Decorators · Van Wert Interior Designers & Decoratorsfreethinker99

iCustomSofa