Attention pros. Need advice

gregmills_gw

10 years ago

Related Stories

HEALTHY HOMEHow to Childproof Your Home: Expert Advice

Safety strategies, Part 1: Get the lowdown from the pros on which areas of the home need locks, lids, gates and more

Full Story

FEEL-GOOD HOMEThe Pros and Cons of Making Your Bed Every Day

Houzz readers around the world share their preferences, while sleep and housekeeping experts weigh in with advice

Full Story

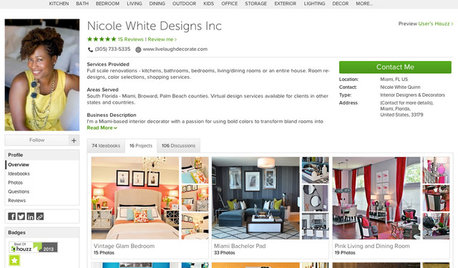

LATEST NEWS FOR PROFESSIONALSFor Home Pros: How to Rock Your Houzz Profile

Attract more clients by putting on your best business face. Here's how

Full Story

LANDSCAPE DESIGNProblem Solving With the Pros: An Abundant Garden Stretches Its Means

Swaths of resilient, eye-catching plants thrive with little care or resources in the landscape of a Pennsylvania farmhouse

Full Story

REMODELING GUIDESFrom the Pros: 8 Reasons Kitchen Renovations Go Over Budget

We asked kitchen designers to tell us the most common budget-busters they see

Full Story

DECORATING GUIDESWorking With Pros: When to Choose Full Design Services

Whether you want a single room or a whole house done, the maximum service level means the least work for you

Full Story

MOST POPULARFrom the Pros: How to Paint Kitchen Cabinets

Want a major new look for your kitchen or bathroom cabinets on a DIY budget? Don't pick up a paintbrush until you read this

Full Story

LANDSCAPE DESIGNProblem Solving With the Pros: Rustic Simplicity in a Country Garden

Editing thoughtfully and adding some magic result in a timeless weekend retreat

Full Story

KITCHEN DESIGNSmart Investments in Kitchen Cabinetry — a Realtor's Advice

Get expert info on what cabinet features are worth the money, for both you and potential buyers of your home

Full Story

DECORATING GUIDESFrom the Pros: How to Paint Interior Walls

A slapdash approach can lower a room's entire look, so open your eyes to this wise advice before you open a single paint can

Full Story

User

gregmills_gwOriginal Author

Related Professionals

Davie Flooring Contractors · Downey Flooring Contractors · Dunedin Flooring Contractors · Gainesville Flooring Contractors · Lynden Flooring Contractors · Salem General Contractors · Albany General Contractors · American Canyon General Contractors · Augusta General Contractors · Bay Shore General Contractors · Erlanger General Contractors · Florida City General Contractors · Hartford General Contractors · Medway General Contractors · Milford Mill General ContractorsMiaOKC

gregmills_gwOriginal Author

User