engineered floor finish

ionized_gw

11 years ago

Related Stories

REMODELING GUIDESWhen to Use Engineered Wood Floors

See why an engineered wood floor could be your best choice (and no one will know but you)

Full Story

KITCHEN DESIGNKitchen Counters: Stunning, Easy-Care Engineered Quartz

There's a lot to like about this durable blend of quartz and resin for kitchen countertops, and the downsides are minimal

Full Story

DECORATING GUIDESFinish Your Floors to Perfection With Parquet

Add value and gorgeous detail to your home with timeless and elegant parquet flooring in a classic design

Full Story

FLOORS11 Distinctive Finishes for Original Floorboards

Whether you go for glossy, painted or matte boards, make your wood floor the star

Full Story

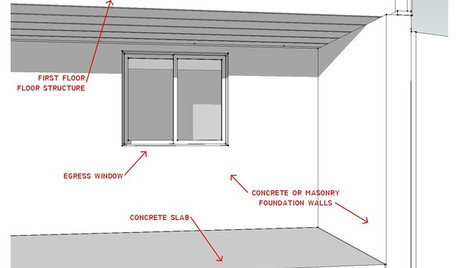

REMODELING GUIDESKnow Your House: The Steps in Finishing a Basement

Learn what it takes to finish a basement before you consider converting it into a playroom, office, guest room or gym

Full Story

REMODELING GUIDESPro Finishing Secret: Aniline Dye for Wood

Deeper and richer than any stain, aniline dye gives wood stunningly deep color and a long-lasting finish

Full Story

REMODELING GUIDESHow to Size Interior Trim for a Finished Look

There's an art to striking an appealing balance of sizes for baseboards, crown moldings and other millwork. An architect shares his secrets

Full Story

KITCHEN DESIGNStylish New Kitchen, Shoestring Budget: See the Process Start to Finish

For less than $13,000 total — and in 34 days — a hardworking family builds a kitchen to be proud of

Full Story

MATERIALSShow Off the Bones of Your Home With Exposed Finishes

There can be beauty in raw materials. Display them with care, and the effect is surprisingly warm and welcoming

Full StoryMore Discussions

live_wire_oak

ionized_gwOriginal Author

Related Professionals

Attleboro Flooring Contractors · Gallatin Flooring Contractors · Monroe Flooring Contractors · Shoreline Flooring Contractors · Stoneham Flooring Contractors · White Bear Lake Flooring Contractors · Lyndon Carpet Dealers · Beloit General Contractors · Converse General Contractors · Enumclaw General Contractors · Hagerstown General Contractors · Highland City General Contractors · Lincoln General Contractors · Summit General Contractors · Waianae General Contractorsglennsfc

ionized_gwOriginal Author

gregmills_gw

gregmills_gw

ionized_gwOriginal Author

GreenDesigns

ionized_gwOriginal Author