Oils for Cutting Boards

Ok, how do we justify putting a petroleum product on a food prep service, as in "food grade" mineral oil on our cutting boards?

I know, I know, other oils go rancid. That's not good either! I checked Wiki, and it said this:

"A light food grade Mineral oil is a good preservative for wooden cutting boards as it helps keep water from seeping into the grain. Alternatively, one may also use a food grade drying oil such as poppyseed oil, tung oil or linseed oil. The first two dry much faster than linseed. Note that most commercially available linseed and tung oil are not "food grade" as they contain metallic driers. In general, edible savory vegetable or olive oils are not recommended because they tend to go rancid, causing the board to smell and your food to pick up the rancid taste."

So, is anyone using poppyseed oil? Is anyone using anything else with success? What about good quality palm oil that is even more stable than coconut oil?

Comments (17)

lectrkbluz

16 years agolast modified: 9 years agoMy father owned five delicatessens and catering businesses. This was before the New York State Department of Health decided to force food businesses to use the white plastic cutting boards. Wood was no longer considered safe. If the wood had any cracks in it, it would leave a place for bacteria to live. I always preferred maple butcher block and I still use it at home today. I worked in all of his businesses and the maple cutting bosrds were never treated with anything. Boards with cracking or seam separating were disposed of or cut down and given to the employees to use at home. I never had a problem with a board and never saw anyone oiling one. I'm sorry I cannot give you a definitive answer, but I hope my comment relieves you idea that a board needs to be treated. I cannot see any problem with wiping a little mineral oil over the surface once a year.

danab_z9_la

16 years agolast modified: 9 years agoRest assured that USP grade or Food Grade Mineral Oil is 100% safe to use on your cutting board. Is it as safe to use as the petroleum derived paraffin wax that can be found on wax paper or in some of our candies. It is the various refining process which remove impurities and makes these products so safe. I am a retired chemist and well acquainted with these petroleum refining processes. Too, I am an avid cook and I sure wouldn't want to expose my family and friends either to any toxic chemicals.

I use mineral oil without hesitation about twice a year on my sole wooden board. I also use it to provide a protective coating on some of my cast iron cookware.......those pieces that I know I will not be using for a long time. Oiling a board will keep it from drying out and cracking. With that said, there may well be other products better suited for oiling a cutting board....but I am not familiar with those other oils.

Dan

plumfield

Original Author16 years agolast modified: 9 years agolektrkbluz, thanks for the feedback. I haven't treated my boards, ever, and they've lasted a good 15 years, but one just split to breaking, and the other one is beginning to split, and I was feeling like I ought to have oiled it. Maybe I'll save the money I was going to spend on a fancy end-grain board, and keep doing what I've been doing, and toss the new ones in another decade or so!

Dan, so glad you feel safe and comfortable with petroleum products. After some of the things I've learned and been through, I'm happy to find even small ways to avoid them, when I can.

bean_counter_z4

16 years agolast modified: 9 years agoI don't use wood boards. If I did I'd buy cheap ones and toss them every few months. BUT. Using mineral oil, wiping off the excess and allowing it to dry would transfer oil to your food in such minute amounts as to be undetectable. Weigh that against the number of bacteria living on wood--not necessarily lethal but not beneficial either. JMHO on things to worry about today.

arley_gw

16 years agolast modified: 9 years agoI use plastic boards for prepping raw meats, and as soon as possible after using them I clean them with antibacterial detergent and lots of hot water.

I'll often use wood boards for carving cooked meats or for prepping vegetables, and I wash them with antibacterial detergent and hot water as well. If I've been messing with something that I know will support bacterial growth well (meat juices are wonderful for that--any bacteriology lab will have some culture media based on beef broth) I'll then slather on about a half ounce to an ounce of cheap vodka, and let it air dry.

I've never oiled a board. My guess is that it's more for appearance and maybe to keep it from cracking, but I doubt that it has much, if any, bacterial-barrier function.

plumfield

Original Author16 years agolast modified: 9 years agoI think the research on this topic is pretty adequate - bacteria don't really like wood, so going hog-wild with bleach and anti-bacterial soaps isn't really necessary. Bacteria do multiply in crevices of plastic rather easily. It is easier to wash plastic, especially since they can often be tossed into the dishwasher.

Simple anti-cross-contamination procedures when handling raw foods is just basic hygiene.

Some research suggests that anti-bacterial soaps contain endocrine disruptors, though. Not like we don't live in a world full of those, anyway, but unless you work at health-care facility or live/work amonng immuno-suppressed individuals, the basic wash-your-hands-with-plain-soap-and-water plan works just fine.

http://faculty.vetmed.ucdavis.edu/faculty/docliver/Research/cuttingboard.htm

http://www.reluctantgourmet.com/cutting_board.

The point of weighing the "danger of bacteria" against mineral oil doesn't hold up as long as normal hygienic practices are maintained. (And because I have a limited number of wooden cutting boards, and use several when I cook, I plop the meats, etc, onto the plastic instead of onto my wood). The amount of mineral oil from the cutting board is insignificant, in the big scheme of things, but if it isn't necessary, why even bother going there? Why let that bottle of mineral oil take up valuable real estate on my shelves when I wouldn't use it for any other purpose? And why choose it if there is a better alternative? That's all I want to know...is there a better alternative. So far, the answer seems to be "no oil at all, but keep the board clean and dry."

gardenlad

16 years agolast modified: 9 years agoGuess I need to chime in here, being as I make custom cutting boards and chopping blocks. So this is something I do know a little about.

First off, recent research has demonstrated what we all knew imperically: Synthetic cutting boards are more likely to support bacterial growth than is wood. There are several reasons for this, and anyone interested can find the info with a quick google search.

The only advantage synthetics have is that you can toss them in a dish washer; something you never want to do with wood. Synthetics are neither cheaper nor bacterially safer than wood, and can often be dangerous to use because the knife edge catches and drags on their surface.

Next, for Arly in particular, but for anyone who uses them. Anti-bacterial soaps have come under fire, lately. Apparently, the studies indicate that they do not do any better job than regular soaps, and they may be contributing to the growth of resistent bacteria.

Personally, I think the jury is still out on that subject, but it's something to be aware of. I've never used them for any purpose, so have no vested interest either way.

Now, as to wooden boards. Oiling is highly recomended for various reasons, not the least of which is that it keeps the wood fibers from drying out and dying. But, whether you oil or not, wood is not likely to harbor bacteria.

In the first place, wood has some anti-bacterial properties of its own. Second, because it dries so quickly after washing, there is no environment to support bacterial growth. Third, a properly constructed board does not become scratched and groved, like a synthetic one, and thus has no caves and crevices to trap food particles and juices and harbor bacteria.

All of this assumes you have not purchased a cheap board.

Cheap boards are made in a flat-grain configuration. That is, they are just like any piece of lumber you are likely to buy. To achieve the cutting board appearance (and to better utilize scraps), they glue them up out of strips. But these boards are likely to warp, twist, crack, craze, and take cut marks from your knives.

Flat grain boards do have a function. They can make nice presentation platters. And, in some cases, because they are subject to so little wear and tear, they are useful as cheese boards.

Cheap is a relative term, too. They are only cheap compared to better made boards. But they aren't really inexpensive. Not when you can go to the lumber yard and buy the equivalent for so much less. Or visit a cabinet maker and likely get it for free from his scrap bin.

Good boards are made one of two ways. The majority of them are made using an edge-grain configuration. To envision how this is done, take a small board and stand it on its long, thin side. The surface you see on top is edge-grain. To make a cutting board, you rip cut the flat board into strips of the appropriate width, and turn each of them on edge. Then glue them together. What had been the width of the strips now becomes the thickness of the board.

Ideally, you will also alternate each strip's grain orientation. This is done by custom makers but not by the mass makers.

Chopping blocks, and high-end cutting boards, are made using an end-grain configuration. Again, start with that common board. Lay it flat, pointing away from you. The thin, short end now facing you is end-grain. Magnify it enough and it will look like a bunch of drinking straws pointing towards you.

If you chop into it the fibers forming the grain separate (picture the straws separating), then come back together in a self-sealing way. That's why they're so good for chopping and butcher blocks.

To make one, you cross-cut the board (usually, but not always, more widely than for a cutting board), stand the pieces on edge, and glue them up. Really thick blocks are sometimes further stabalized with dowel rods, threaded metal rods, and strapping.

Really top of the line cutting boards are made using both configurations. First an end-grain board is constucted. This is then cut into strips to make the final edge-grain block. Such boards often have a checkerboard pattern inherent because of the double cutting & glueing this entails.

BTW, Plumfield, where you quote the use of drying oils. Anyone trying that should be aware that drying oils merely form a coating on the surface, which has to be renewed often to do any good. They do not penetrate deep into the fibers to preserve and protect the living wood. Which is what mineral oil does do.

Whether you oil or not is a personal decision. Those of us with a respect and feeling for the wood as a living thing will oil. Others may not.

For those who do oil, there is a recommended schedule, which I'll be glad to share if anyone wants it.

pratzert

16 years agolast modified: 9 years agoI use the white plastic cutting boards, but to help keep things clean and bacteria free, I keep a spray bottle with a Bleach & Water solution by my sink.

I spray my cutting board AND counter top with the solution occasionally, but always after cutting up meats or chicken.

Tim

plumfield

Original Author16 years agolast modified: 9 years agoGardenlad, thanks for your post, I really appreciate your input since you actually make boards.

Earlier today, I got to thinking about beeswax, and recalled that somewhere on the internet I had seen a product that combined some sort of oil with beeswax, and I think they used it on cutting boards, but I'm not one hundred percent sure I'm remembering that correctly.

Now, I love the idea of beeswax. Do you have any experience with or any opinions on using beeswax on cutting boards, either with or without oil?

The other thought I had (oh my, I know I sound SO paranoid), what kind of glue do you use when you construct boards, and did you choose that brand/type based on its level of toxicity?

I'm sure there will be people interested in knowing what a cutting board maker recommends when it comes to oiling routines, so I hope you share that.

snookums

16 years agolast modified: 9 years agogardenlad - boy am I glad I saw your post. I have in my mind an idea of the cutting board that I want, but it doesn't exist. Boos makes several boards that each have one feature of what I want, but when I e-mailed them to ask about something custom or to purchase feet to adjust my own, I got quite a nasty response from them. I wound up buying a cheap one from HomeGoods (which does seem to be ok quality with end-grain checkerboard construction) until I can find the one I really want. Maybe you can make it for me. Can you e-mail me at sharon cc @ cox . net ? (eliminate the spaces) I don't always remember to check this board - I normally post on others but came here to find out about oiling my new inexpensive one. I have some pure tung oil here and I wasn't sure if it was ok to use it or not. I'd love to talk to you about what I'd like in a cutting board. Thanks!!

Thanks!

plumfield

Original Author16 years agolast modified: 9 years agogardenlad and snookums,

I just looked up tung oil and found some interesting information about it at:

http://www.realmilkpaint.com/oil.htmlAnd to make it penetrate, they recommend using a natural citrus solvent on the first coat of oil. They talk about their citrus product on this page:

http://www.realmilkpaint.com/citrus.htmlSnookums, thanks for mentioning tung oil. It sure looks good to me!

Gardenlad, will you give us the benefit of your experience on this oil?

gardenlad

16 years agolast modified: 9 years agoSnookums, you have mail.

Plumfield, although I've used tung oil on gunstocks and small projects like jewelery boxes, it never occured to me to use it on a cutting board.

I'm not convinced it is foodsafe, to begin with. And even with additives, it doesn't penetrate that deeply. Essentially, it bonds with the surface fibers of the wood to form a fairly tough surface. This is what you want on highly finished items like gunstocks, furniture, and accent pieces. But not what you're looking for on a cutting board.

I think you hit it on the nose. Glue & toxicity reflect a level of paranoia I can't relate to---and I used to be in the intelligence business, where the watchword was "of course I'm paranoid, but am I paranoid enough." I choose glues based on their efficacy for the job. For a cutting board that means when they set up they form a permanent bond with the wood fibers and are waterproof.

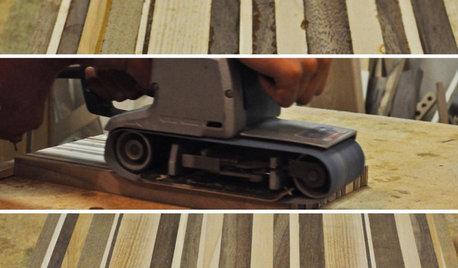

As to oiling schedule. My boards come to you already well oiled, so, in a pinch, you can skip the first application. But in general, using mineral oil (because it is food safe and does not discolor the wood) you want to oil once a week for the first month. Once every two weeks for the second month. Once a month for the next six months. Then annually after that.

To oil the board, pour some oil on the surface and spread it around with your hand, applying slight pressure, and rubbing in a circular motion. There should be a shiny film over the entire surface. If there are dull spots it means the wood is absorbing it faster there. Rub on a little more.

Let the board sit for a couple of hours. Wipe off any excess. Repeat on the other side.

Don't forget to oil the sides as well as the top surfaces.

plumfield

Original Author16 years agolast modified: 9 years agoThanks for your take on tung oil...I did a little more research and found it was made from a poisonous seed. Two reasons to move on!

And Thanks for the oiling schedule...

cajunliberty7

9 years agoRaw linseed (flaxseed, or flax oil) is readily available on Amazon.com and via even local sources for me. Because the raw does not have a chemical drier in it, it is good to eat, drink, coat your cutting board, gun stock, and perform innumerable culinary and preservative actions with it. One word of caution with the raw linseed. It takes often several days or more to absorb fully. I have used it to coat butcher block, wood cutting boards, wood knife handles, gun stocks, antiques, and my new cedar planters to keep them from turning gray and help them to not split.

petalique

8 years agoI read that wooden boards, when dried, do not harbor bacteria. I use a variety of cutting boards. My two favorites are hard maple. The very large on isy pastry and bread dough board. It never sees water. I use a bench scraper, then a clean damp white cotton terry before storing it (end on).

The other, smaller ?Vermont hard maple board I use for anything -- mostly vegetables, but not sopping wet ones. If I slice bread on a nice board, I don't press down past the bottom crust or perhaps lift it. A friend learned that from an experienced German baker.

I wipe this board w a clean white terry cloth, damp, not wet. Water or sopping wet good ruin wood. I often add a bit of chlorine bleach to my light soap and water, wring out till damp. Wipe w clear barely damp clean cloth. Store vertically on edge.

I do not put oil on my boards, but if I were to, I would use a thin coat of fine mineral oil, then wipe it off. Oil can collect dust and odors.

For something like watery meat, chicken, lobster guts <g>, I use the plastic/nylon boards that I also clean up w bleach soap and water and or run through the dishwasher. I have bamboo boards too and these are easy to clean (wipe, never soak, never dishwasher).

I think non-bamboo hardwoods are the kindest to sharp knife edges. Just clean up as you go along.

BTW, I never put food prepping knives that I value in the dishwasher, nor do I leave them in the sink where the blade can get chipped or the handle get mongey. Quick wash and rinse and dry take less time than opening the catalog to find a replacement. And not a good knives need to cost a lot.

If my boards want to slide or rock on a solid surface, I put a few small silicone cupboards door quiet stop circles here and there.

I love hardwood cutting / pastry boards!

charon70

8 years agoGarland, is their a particular company you would recommend to purchase an edge grain board? Williams Sonoma sells edge grain boards. Do you recommend those?

printzilla