engine missing

bmans05

15 years ago

Related Stories

REMODELING GUIDESWhen to Use Engineered Wood Floors

See why an engineered wood floor could be your best choice (and no one will know but you)

Full Story

REMODELING GUIDES10 Features That May Be Missing From Your Plan

Pay attention to the details on these items to get exactly what you want while staying within budget

Full Story

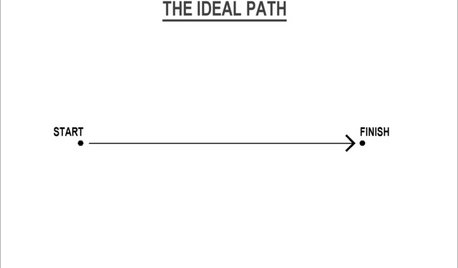

MOST POPULARThe Many Paths of Design, Part 1

Blame engineering issues, unforeseen revisions or even the Internet. As these diagrams show, it's probably not your fault

Full Story

HOUZZ TOURSMy Houzz: Reinventing a 1930 Fire Station for Family Life

Don't sound the alarm because the fire engine is gone; this remodeled station now happily hosts fundraisers and two generations of a family

Full Story

PRODUCT PICKSGuest Picks: Robot Love

This funky robot decor will inspire budding engineers and give your home a techie-chic touch

Full Story

I Spy: Eiffel Towers Around the House

A 19th-century feat of engineering adds French flair to décor

Full Story

HOUZZ TOURSHouzz Tour: Manhattan Brownstone Hides a Surprise

Behind an unassuming residential facade on an East Village street dotted with storefronts lies a feat of engineering

Full Story

HOUZZ TOURSMy Houzz: Rustic Meets Refined in a Converted Ohio Barn

Intelligent reuse and innovative engineering create a modern family home that’s anything but typical

Full Story

BLACKHow to Decorate With Brown, Black — or Both

Black is best for engineered materials; brown works great for textures — and more designer tips for working with these two classic colors

Full Story

WORKING WITH PROS6 Reasons to Hire a Home Design Professional

Doing a construction project without an architect, a designer or a design-build pro can be a missed opportunity

Full StorySponsored

Central Ohio's Trusted Home Remodeler Specializing in Kitchens & Baths

gary__

jemdandy

Related Discussions

Toro Mower Misfire

Q

Lawn Tractor stalls while driving uphill

Q

Briggs 3.75hp engine missing

Q

Floor Joists and Main Beam Sizing

Q

john_g

jemdandy

john_g

jemdandy

john_g

bmans05Original Author

gary__

jemdandy

gary__