Zip vs Tyvek/insulation type?

rmverb

9 years ago

Featured Answer

Sort by:Oldest

Comments (19)

energy_rater_la

9 years agoworthy

9 years agoRelated Professionals

Ann Arbor Architects & Building Designers · Clayton Home Builders · Lansing Home Builders · Westwood Home Builders · Buenaventura Lakes Home Builders · Murraysville General Contractors · Annandale General Contractors · Hillsborough General Contractors · Lake Forest Park General Contractors · Newburgh General Contractors · Roselle General Contractors · Rowland Heights General Contractors · Schertz General Contractors · Shorewood General Contractors · Springboro General Contractorsrmverb

9 years agoenergy_rater_la

9 years agoUser

9 years agoBrianKnight

9 years agoshifrbv

9 years agoUser

9 years agormverb

8 years agoPrateek Shah

8 years agoUser

8 years agolast modified: 8 years agoPrateek Shah

8 years agoUser

8 years agolast modified: 8 years agoPrateek Shah

8 years agoUser

8 years agolast modified: 8 years agoUser

8 years agolast modified: 8 years agoJustin McCullough

8 years agoqbryant

8 years ago

Related Stories

GREEN BUILDINGInsulation Basics: Designing for Temperature Extremes in Any Season

Stay comfy during unpredictable weather — and prevent unexpected bills — by efficiently insulating and shading your home

Full Story

GREEN BUILDINGInsulation Basics: Heat, R-Value and the Building Envelope

Learn how heat moves through a home and the materials that can stop it, to make sure your insulation is as effective as you think

Full Story

GUESTHOUSESA Hideaway for All Ages Perched Among the Trees in Maine

A modern Adirondack ‘treehouse’ is designed as a place for playing games, reading, sleeping over and enjoying forest views

Full Story

WINDOWSContractor Tips: How to Choose and Install Windows

5 factors to consider when picking and placing windows throughout your home

Full Story

HOMES AROUND THE WORLDMy Houzz: Small-Space Living on a Barge Awash With Smart Ideas

This newly built barge moored on London’s Regent’s Canal brims with clever designs and luxe touches, proving small can be very beautiful

Full Story

REMODELING GUIDESOne Guy Found a $175,000 Comic in His Wall. What Has Your Home Hidden?

Have you found a treasure, large or small, when remodeling your house? We want to see it!

Full Story

REMODELING GUIDESContractor Tips: 5 Easy Ways to Get a Greener Home

Forget a fleet of solar panels (for now). These ideas can make your home a whole lot greener when money or time is in short supply

Full Story

HOUZZ TOURSHouzz Tour: Modern Warmth for a Lake Superior Getaway

Wood and glass aplenty help a lakeside vacation home reflect its surroundings while opening to the view

Full Story

Replace Your Windows and Save Money — a How-to Guide

Reduce drafts to lower heating bills by swapping out old panes for new, in this DIY project for handy homeowners

Full Story

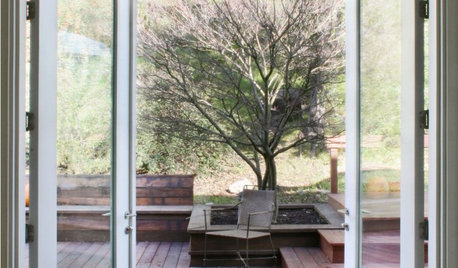

MOST POPULARFind the Right Glass Door for Your Patio

It’s more than just a patio door — it’s an architectural design element. Here’s help for finding the right one for your home and lifestyle

Full Story

User