This is a repeat post of one from several years back by a long time poster, builder, and gardenweb member: Rollie. I thought it was a brilliant idea and wanted to share with all you new builders . . .

2004 thread from the Internet Archive Wayback Machine - http://www.archive.org/web/web.php

http://web.archive.org/web/20041211181322/ths.gardenweb.com/forums/load/build/msg1110381520518.html

I added pictures & some descriptions linked from Rollie's website "Delores House" http://imageevent.com/okoboji_images/deloreshouse

How clean is too clean, Part 2

Posted by Rollie (My Page) on Wed, Nov 3, 04 at 10:38

A while back, there was a post about how to clean the subfloors up after the construction was done, and how clean they needed to be before finished floors can be installed. There were lots of good posts, but it has dropped off of the page.

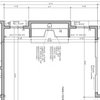

I took some early shots of a project, where I explained that we cover the subfloor with 30 lb felt paper before any framing occurs, then we frame on top of it, and cut it out after final painting is done. Here is a series of pictures that show a couple different stages, and how clean the floor is when we finally strip off the felt.

Framing on top of felt: 30 lb felt covering Advantech. Total time involved 1 1/2 hrs, 2 men. 1400sft, at 200sf per roll,= 7 rolls at $15.80 each = $115 total

After drywall and painting: As you can see, there is considerable dirt, dust, mud, drywall compound etc that collects on this membrane. All of this residue rolls up, is removed from the structure, and is thrown away, leaving the subfloor very clean.

Here you see some prep being done. The Roll-Lath is pulled up, and 90 % of the staples comes with it if you use 1/4 inch staple to hold it down. If you use anything longer, expect to spend time plucking staples and tabs of felt up from the floor. We cut around the perimeter, so we dont get tar marks on the wall when rolling it up. This is especially important when the walls are finish painted. (Usually, I wait till after the finish painting is done, but I couldnt do it in this situation of 3 pics below. Since we were going with infloor hydronic heat we needed to remove the felt protection, to install the wirsbo piping and the 1 1/2" gypcrete cover)

After removal of felt, ready for finish carpentry:

Make sure and run the staples parallel to the roll lath, and they will come up easier.

Note the staple lines: Use of 1/4 inch staples is recommended to eliminate the staples staying in the subfloor like shown in the last picture. 1/4 inch staples will roll right up with the two layers of felt. These guys did not have 1/4 in, and used 3/8 instead. Bad mistake, as they are now learning, as its a real PITA to remove the tabs of felt and staples left behind, although usually it only needs to be done where there is hard surface, and not carpet and pad.

The black marks on the subfloor is some of the asphalt base that leaches out into the subfloor and causes some discoloration.

RE: How clean is too clean, Part 2

Posted by: Rollie (My Page) on Sun, Nov 7, 04 at 23:42

We do felt on a slab also, but usually after framing, at which time you can usually use 15lb felt. I would advise against plastic, as it is too slippery when wet, and it will get wet. When felting a slab floor, we use duct tape to tape all of the seams, and then just roll up the complete mess and haul it out.

We have tried most methods, and have settled on this approach as the most bang for the buck. Covering multiple times is not cost effective, and never achieves the same results as covering before.

As far as cost is concerned, it takes considerably less time to cover a floor before the framing is done, and when the subfloor is new, as opposed to covering all the different rooms individually. Believe me, this approach has been looked at several times, and is considered to be the most cost effective in terms of return. I actually started doing this while building my own personal house, and have implemented it into the homes we build for customers. 15 lb felt does not have the lifespan to withstand the rigors of framing, subs, equipment, drywall and painting, 30 lb will, but like I said, make sure you use 1/4 inch legs on the staples.

Maybe its not for everyone, and I hope I dont come across that way, Only offering something different that works for me, and is appreciated by my customers.

THINGS I HAVE TO ADD : When Rollie first posted this thread, I think he was using 2 layers of 30#felt. But it sounds like from the Delores house descriptions (which he built in 2005) that he has changed to 1 layer ? An idea that I had and have no idea if this would work : since the felt leaves a little bit of stain on subfloor, maybe heavy brown contractor paper can be laid down and then felt on top of it. Another idea I had (for drywall only) - sweep subfloor & lay heavy brown contractor paper before drywallers. They leave an big mess which is tough to get off subfloor. - Angela

rollie

wear_your_baby

Related Professionals

Asbury Park Architects & Building Designers · Washington Architects & Building Designers · Oak Grove Design-Build Firms · Kaysville Home Builders · Manassas Home Builders · Clarksville General Contractors · Coronado General Contractors · Coshocton General Contractors · Forest Grove General Contractors · Hutchinson General Contractors · Montebello General Contractors · Mount Vernon General Contractors · Parma General Contractors · Van Buren General Contractors · Waianae General Contractorsangela12345Original Author

rollie

worthy

rollie

sierraeast

angela12345Original Author

angela12345Original Author

sierraeast