Least Toxic Insulation Products?

tuifeathers

10 years ago

Featured Answer

Sort by:Oldest

Comments (8)

Oaktown

10 years agoEpiarch Designs

10 years agoRelated Professionals

Baton Rouge Architects & Building Designers · Yorkville Design-Build Firms · University Park Home Builders · Colorado Springs Home Builders · Garland Home Builders · Vista Park Home Builders · American Canyon General Contractors · Arkansas City General Contractors · Cape Girardeau General Contractors · Lakeside General Contractors · Norristown General Contractors · Tabernacle General Contractors · Uniondale General Contractors · Valley Stream General Contractors · Wheaton General Contractorsenergy_rater_la

10 years agoibewye

10 years agojohn_wc

10 years agotuifeathers

10 years agoBrian_Knight

10 years ago

Related Stories

MATERIALSInsulation Basics: What to Know About Spray Foam

Learn what exactly spray foam is, the pros and cons of using it and why you shouldn’t mess around with installation

Full Story

GREEN BUILDINGEcofriendly Cool: Insulate With Wool, Cork, Old Denim and More

Learn about the pros and cons of healthier alternatives to fiberglass and foam, and when to consider an insulation switch

Full Story

REMODELING GUIDESCool Your House (and Costs) With the Right Insulation

Insulation offers one of the best paybacks on your investment in your house. Here are some types to discuss with your contractor

Full Story

WINDOW TREATMENTSEasy Green: 9 Low-Cost Ways to Insulate Windows and Doors

Block drafts to boost both warmth and energy savings with these inexpensive but effective insulating strategies

Full Story

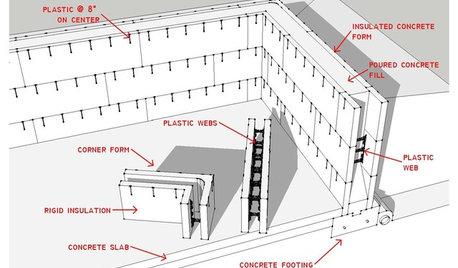

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

GREEN BUILDINGInsulation Basics: Natural and Recycled Materials

Consider sheep’s wool, denim, cork, cellulose and more for an ecofriendly insulation choice

Full Story

GREEN BUILDINGInsulation Basics: Heat, R-Value and the Building Envelope

Learn how heat moves through a home and the materials that can stop it, to make sure your insulation is as effective as you think

Full Story

GREEN BUILDINGInsulation Basics: Designing for Temperature Extremes in Any Season

Stay comfy during unpredictable weather — and prevent unexpected bills — by efficiently insulating and shading your home

Full Story

SHOP HOUZZHouzz Products: Set Up Your Dream Coffee Station

Wouldn’t it be nice to have your own café that never closes? With these tools and accessories from the Houzz Products section, you can

Full Story

HEALTHY HOMEDetox Your Kitchen for the Healthiest Cooking

Maybe you buy organic or even grow your own. But if your kitchen is toxic, you're only halfway to healthy

Full Story

dadereni