New Home efficiency options

TravisinHV

10 years ago

Related Stories

HOUZZ TOURSHouzz Tour: Energy-Efficient, 'Lean' House in Maine

Sustainable architecture and amazing light draw an environmentally conscious family to a new home

Full Story

MODERN STYLEHouzz Tour: Hilltop Home With a View to Energy Efficiency

A contemporary light-filled English home makes the most of its location

Full Story

BARN HOMESHouzz Tour: An Energy-Efficient Barn Graces the Nebraska Landscape

Passive-house technologies and a rain-harvesting and greywater system conserve natural resources in this weekend country home

Full Story

GREAT HOME PROJECTSUpdate Your Windows for Good Looks, Efficiency and a Better View

Great home project: Replace your windows for enhanced style and function. Learn the types, materials and relative costs here

Full Story

HOUZZ TOURSHouzz Tour: Artful and Efficient in Austin

Visit a home that glows with local materials, thoughtful design, heritage trees and Moontowers

Full Story

GREEN BUILDINGEfficient Architecture Suggests a New Future for Design

Homes that pay attention to efficient construction, square footage and finishes are paving the way for fresh aesthetic potential

Full Story

REMODELING GUIDESUpdate Historic Windows for Charm and Efficiency

Renovate old windows to keep the character but lose the energy outflow from your home

Full Story

LIGHTINGThe Lowdown on High-Efficiency LED Lighting

Learn about LED tapes, ropes, pucks and more to create a flexible and energy-efficient lighting design that looks great

Full Story

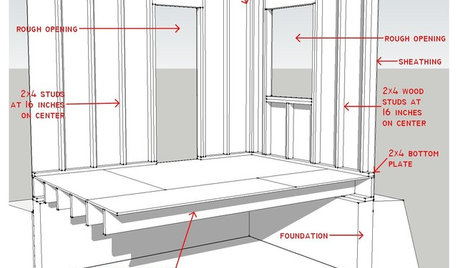

REMODELING GUIDESKnow Your House: Components of Efficient Walls

Learn about studs, rough openings and more in traditional platform-frame exterior walls

Full Story

LAUNDRY ROOMSHouzz Call: Show Us Your Wonderfully Efficient Laundry Room

Got a drying rack, a folding table or clever storage in your laundry room? We want to see it!

Full StorySponsored

Central Ohio's Trusted Home Remodeler Specializing in Kitchens & Baths

More Discussions

energy_rater_la

Annie Deighnaugh

Related Professionals

Memphis Architects & Building Designers · Mililani Town Design-Build Firms · Big Bear City Home Builders · Ives Estates Home Builders · Los Banos Home Builders · Vista Park Home Builders · Wilmington Home Builders · Wilmington Home Builders · Ashtabula General Contractors · Belleville General Contractors · Greenville General Contractors · Manalapan General Contractors · Rock Island General Contractors · West Whittier-Los Nietos General Contractors · Westchester General Contractorsrobin0919

Epiarch Designs

worthy

Brian_Knight

TravisinHVOriginal Author

energy_rater_la

robin0919

energy_rater_la

Brian_Knight

bridget helm