Gaps in house wrap

jdez

10 years ago

Related Stories

GARDENING AND LANDSCAPINGThat Gap Under the Deck: Hide It or Use It!

6 ways to transform a landscape eyesore into a landscape feature

Full Story

GARDENING AND LANDSCAPINGBoardwalks Bridge the Gap to Nature

Previously inaccessible parts of the landscape can roll out the welcome mat with help from these clever and beautiful pathways

Full Story

ARCHITECTURERibbon Houses, Wrapped in Style

Bold Continuous Lines Unify Floors, Walls and Ceilings

Full Story

HOUZZ TOURSMy Houzz: A Classic Midcentury Home Wrapped in Windows

A couple's 4-year restoration and renovation results in a bright look for their wood-paneled house in New York

Full Story

CONTEMPORARY HOMESHouzz Tour: Dappled Light Inspires Artistic Wrapping

Cor-Ten cut with circles mimics the effect of a massive pine tree’s canopy, for a striking look inside and out

Full Story

REMODELING GUIDESArchitect's Toolbox — Trim Wraps Up Style for Rooms

Dynamic 'ribbons' of trim work wonders to provide that important finishing touch and set off your room's architecture

Full Story

LIVING ROOMSRoom of the Day: Wrapped in Blues and Silvery Hues

Chic and comfortable, this coastal Rhode Island living room honors its classic architecture but keeps things fresh with a cool palette

Full Story

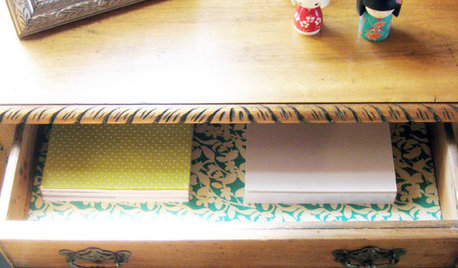

DECORATING GUIDES10 Ways to Reuse Wrapping Paper

Don't just toss your prettiest paper in the trash or recycling bin — gift wrap scraps can make wonderful home decor

Full Story

HOLIDAYS9 Ultimate Gift Wrapping and Crafts Stations

Ribbons spooling through an open door; colored paper nipping at your nose — workstations like these make the holiday season even brighter

Full Story

ARCHITECTUREHouzz Tour: A Vintage Home Wrapped Up in a Box

A work-at-home couple completes an eye-catching contemporary renovation that builds on an Arts and Crafts home

Full StoryMore Discussions

worthy

jennybc

Related Professionals

Euless Architects & Building Designers · Hockessin Architects & Building Designers · Royal Palm Beach Architects & Building Designers · South Lake Tahoe Architects & Building Designers · Riverbank Home Builders · Seguin Home Builders · Vista Park Home Builders · Auburn General Contractors · Big Lake General Contractors · Franklin General Contractors · Kentwood General Contractors · Markham General Contractors · South Windsor General Contractors · Universal City General Contractors · Austintown General Contractorsrenovator8

_sophiewheeler

jdezOriginal Author

worthy

worthy

renovator8

jdezOriginal Author

virgilcarter

rollie

robin0919

kirkhall

jdezOriginal Author

Oaktown

jdezOriginal Author

worthy

renovator8

jdezOriginal Author

millworkman

virgilcarter

renovator8

rollie

renovator8

virgilcarter

jdezOriginal Author

renovator8

Awnmyown

worthy

renovator8