Attic I Insulation Help On New Construction

Central79

11 years ago

Related Stories

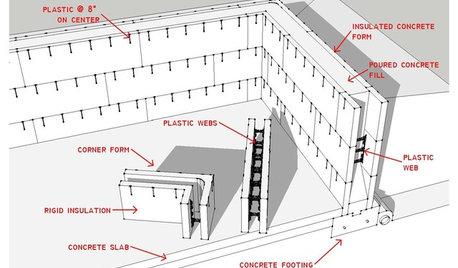

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

MATERIALSInsulation Basics: What to Know About Spray Foam

Learn what exactly spray foam is, the pros and cons of using it and why you shouldn’t mess around with installation

Full Story

REMODELING GUIDESCool Your House (and Costs) With the Right Insulation

Insulation offers one of the best paybacks on your investment in your house. Here are some types to discuss with your contractor

Full Story

GREEN BUILDINGInsulation Basics: Heat, R-Value and the Building Envelope

Learn how heat moves through a home and the materials that can stop it, to make sure your insulation is as effective as you think

Full Story

GREEN BUILDINGEcofriendly Cool: Insulate With Wool, Cork, Old Denim and More

Learn about the pros and cons of healthier alternatives to fiberglass and foam, and when to consider an insulation switch

Full Story

GREEN BUILDINGInsulation Basics: Designing for Temperature Extremes in Any Season

Stay comfy during unpredictable weather — and prevent unexpected bills — by efficiently insulating and shading your home

Full Story

GREEN BUILDINGInsulation Basics: Natural and Recycled Materials

Consider sheep’s wool, denim, cork, cellulose and more for an ecofriendly insulation choice

Full Story

WINDOW TREATMENTSEasy Green: 9 Low-Cost Ways to Insulate Windows and Doors

Block drafts to boost both warmth and energy savings with these inexpensive but effective insulating strategies

Full Story

REMODELING GUIDESWisdom to Help Your Relationship Survive a Remodel

Spend less time patching up partnerships and more time spackling and sanding with this insight from a Houzz remodeling survey

Full Story

STANDARD MEASUREMENTSKey Measurements to Help You Design Your Home

Architect Steven Randel has taken the measure of each room of the house and its contents. You’ll find everything here

Full Story

worthy

david_cary

Related Professionals

Fayetteville Architects & Building Designers · Franklin Architects & Building Designers · Palmer Architects & Building Designers · Nanticoke Architects & Building Designers · Syracuse Architects & Building Designers · Midlothian Home Builders · Reedley Home Builders · Fremont General Contractors · Hammond General Contractors · Jackson General Contractors · Ken Caryl General Contractors · Mineral Wells General Contractors · Mira Loma General Contractors · New Milford General Contractors · Newington General ContractorsCentral79Original Author

energy_rater_la

Brian_Knight

worthy

Central79Original Author

energy_rater_la

Central79Original Author

Brian_Knight

worthy

david_cary

energy_rater_la

worthy

worthy

worthy

Central79Original Author

Central79Original Author

energy_rater_la

david_cary

Brian_Knight

DevinR

david_cary

worthy

Brian_Knight

worthy

Brian_Knight

momto3kiddos

energy_rater_la

momto3kiddos

energy_rater_la

Epiarch Designs

Epiarch Designs

energy_rater_la

Central79Original Author

energy_rater_la