insulating for sound

mooniac2007

16 years ago

Related Stories

GREEN BUILDINGInsulation Basics: Heat, R-Value and the Building Envelope

Learn how heat moves through a home and the materials that can stop it, to make sure your insulation is as effective as you think

Full Story

REMODELING GUIDESCool Your House (and Costs) With the Right Insulation

Insulation offers one of the best paybacks on your investment in your house. Here are some types to discuss with your contractor

Full Story

GREEN BUILDINGEcofriendly Cool: Insulate With Wool, Cork, Old Denim and More

Learn about the pros and cons of healthier alternatives to fiberglass and foam, and when to consider an insulation switch

Full Story

GREEN BUILDINGInsulation Basics: Natural and Recycled Materials

Consider sheep’s wool, denim, cork, cellulose and more for an ecofriendly insulation choice

Full Story

WINDOW TREATMENTSEasy Green: 9 Low-Cost Ways to Insulate Windows and Doors

Block drafts to boost both warmth and energy savings with these inexpensive but effective insulating strategies

Full Story

MATERIALSInsulation Basics: What to Know About Spray Foam

Learn what exactly spray foam is, the pros and cons of using it and why you shouldn’t mess around with installation

Full Story

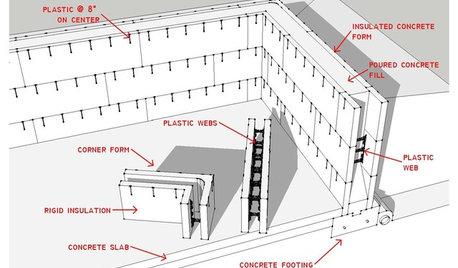

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

HOUSEKEEPINGWhat's That Sound? 9 Home Noises and How to Fix Them

Bumps and thumps might be driving you crazy, but they also might mean big trouble. We give you the lowdown and which pro to call for help

Full Story

HOME TECHWhat Chipotle and Radiohead Can Teach Us About Sound Quality at Home

Contemporary designs filled with glass and concrete can be hostile environments for great sound quality. Here's how to fix that

Full Story

THE ART OF ARCHITECTURESound Advice for Designing a Home Music Studio

How to unleash your inner guitar hero without antagonizing the neighbors

Full Story

worthy

anthem

Related Professionals

Frisco Architects & Building Designers · Salem Home Builders · Troutdale Home Builders · Cibolo General Contractors · Converse General Contractors · Genesee General Contractors · Mansfield General Contractors · Mount Prospect General Contractors · North Highlands General Contractors · North New Hyde Park General Contractors · Pinewood General Contractors · Prichard General Contractors · Rossmoor General Contractors · Torrington General Contractors · Waxahachie General Contractorsmightyanvil

worthy

brutuses

anthem

jj4444444

mightyanvil

canoe98