Please help with prep for tile and a washer dryer stack

enduring

10 years ago

Related Stories

MONTHLY HOME CHECKLISTSYour Checklist for Quick Houseguest Prep

Follow these steps to get your home ready in a hurry for overnight visitors

Full Story

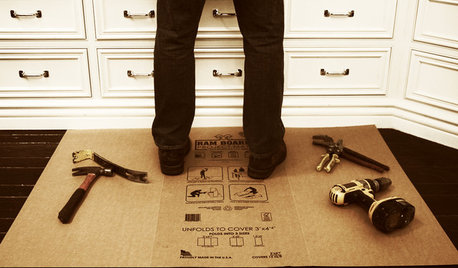

BATHROOM DESIGNOut With the Old Tile: 8 Steps to Prep for Demolition

This isn't a light DIY project: You'll need heavy-duty tools and plenty of protection for your home and yourself

Full Story

SELLING YOUR HOUSE10 Tricks to Help Your Bathroom Sell Your House

As with the kitchen, the bathroom is always a high priority for home buyers. Here’s how to showcase your bathroom so it looks its best

Full Story

SELLING YOUR HOUSEFix It or Not? What to Know When Prepping Your Home for Sale

Find out whether a repair is worth making before you put your house on the market

Full Story

HOME OFFICESQuiet, Please! How to Cut Noise Pollution at Home

Leaf blowers, trucks or noisy neighbors driving you berserk? These sound-reduction strategies can help you hush things up

Full Story

ORGANIZINGDo It for the Kids! A Few Routines Help a Home Run More Smoothly

Not a Naturally Organized person? These tips can help you tackle the onslaught of papers, meals, laundry — and even help you find your keys

Full Story

MOVINGRelocating Help: 8 Tips for a Happier Long-Distance Move

Trash bags, houseplants and a good cry all have their role when it comes to this major life change

Full Story

ENTERTAININGGenius Home Prep: A Guest Room in a Box

No dedicated guest room? Make hosting overnighters easier by keeping the essentials in one place

Full Story

REMODELING GUIDESContractor Tips: Advice for Laundry Room Design

Thinking ahead when installing or moving a washer and dryer can prevent frustration and damage down the road

Full Story

KITCHEN DESIGNKey Measurements to Help You Design Your Kitchen

Get the ideal kitchen setup by understanding spatial relationships, building dimensions and work zones

Full Story

weedyacres

enduringOriginal Author

Related Professionals

Ballenger Creek Kitchen & Bathroom Designers · Georgetown Kitchen & Bathroom Designers · Rancho Mirage Kitchen & Bathroom Designers · Garden Grove Kitchen & Bathroom Remodelers · Gilbert Kitchen & Bathroom Remodelers · Glen Allen Kitchen & Bathroom Remodelers · Lynn Haven Kitchen & Bathroom Remodelers · Mooresville Kitchen & Bathroom Remodelers · Rancho Cordova Kitchen & Bathroom Remodelers · South Barrington Kitchen & Bathroom Remodelers · Alton Cabinets & Cabinetry · Ridgefield Cabinets & Cabinetry · Berkley Window Treatments · Orange County Window Treatments · South Yarmouth Window Treatmentspricklypearcactus

enduringOriginal Author

MongoCT

enduringOriginal Author

MongoCT

MongoCT

enduringOriginal Author

MongoCT

enduringOriginal Author

enduringOriginal Author