Bill V and others, is a metal mesh embedded in cement-like...

threeapples

11 years ago

Related Stories

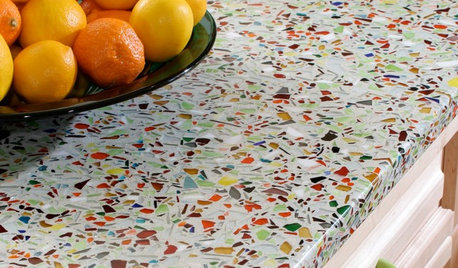

KITCHEN DESIGNKitchen Counters: Sturdy, Striking Recycled Glass With Cement

Ecofriendly and full of character, this heat- and scratch-resistant material is a great fit for custom kitchen counters

Full Story

REMODELING GUIDESMaterials: The Advantages of a Metal Roof

Metal reigns in roofing style, maintenance and energy efficiency

Full Story

FUN HOUZZDon’t Be a Stickybeak — and Other Home-Related Lingo From Abroad

Need to hire a contractor or buy a certain piece of furniture in the U.K. or Australia? Keep this guide at hand

Full Story

MOST POPULARWhat to Know About Adding a Deck

Want to increase your living space outside? Learn the requirements, costs and other considerations for building a deck

Full Story

ARCHITECTUREHouzz Tour: Shipping Containers Make for an Unusual Home

Recycling hits the big time as a general contractor turns 4 metal boxes into a decidedly different living space

Full Story

ARCHITECTUREDesign Workshop: The Beauty of Humble Materials

Discover the appeal of budget-friendly plywood, concrete and other modest surfaces

Full Story

PETSSo You Want to Get a Cat

If you're a cat lover, the joys outweigh any other issue. If you haven't lived with one yet, here are a few things to know

Full Story

DECORATING GUIDESRoom of the Day: Playing Up Color in a California Lounge

Candy-licious stripes and splashes of other lively hues show that this hangout for teens and their parents is ready for fun

Full Story

REMODELING GUIDESContractor Tips: How to Install Tile

Before you pick up a single tile, pull from these tips for expert results

Full Story

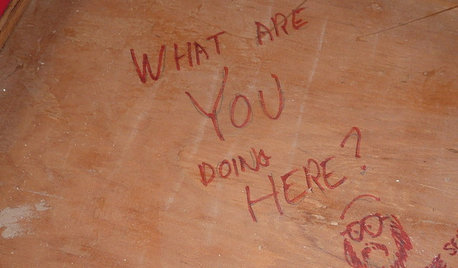

FUN HOUZZDoes Your Home Have a Hidden Message?

If you have ever left or found a message during a construction project, we want to see it!

Full Story

Tim

millworkman

Related Professionals

Leicester Kitchen & Bathroom Designers · Newington Kitchen & Bathroom Designers · Owasso Kitchen & Bathroom Designers · Vineyard Kitchen & Bathroom Designers · Grain Valley Kitchen & Bathroom Remodelers · Weston Kitchen & Bathroom Remodelers · Allentown Cabinets & Cabinetry · Berkeley Heights Cabinets & Cabinetry · Farmers Branch Cabinets & Cabinetry · Lindenhurst Cabinets & Cabinetry · Plymouth Cabinets & Cabinetry · Salisbury Cabinets & Cabinetry · Saint James Cabinets & Cabinetry · Antioch Window Treatments · The Woodlands Window Treatmentscatbuilder

threeapplesOriginal Author

threeapplesOriginal Author

gbsim1

enduring

Tim

catbuilder

threeapplesOriginal Author

mcclelland

threeapplesOriginal Author

catbuilder

gbsim1

threeapplesOriginal Author

gbsim1

millworkman

threeapplesOriginal Author

threeapplesOriginal Author

millworkman

MongoCT

brickeyee

catbuilder

threeapplesOriginal Author

gbsim1

catbuilder

GreenDesigns

ctlady_gw

threeapplesOriginal Author

catbuilder

MongoCT

KevinMP

gbsim1

threeapplesOriginal Author

enduring

MongoCT

GreenDesigns

threeapplesOriginal Author

threeapplesOriginal Author

Vertise

threeapplesOriginal Author

kirkhall

Vertise