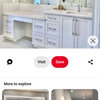

Material for paint grade vanities

Betsey Thompson

12 years ago

Related Stories

BATHROOM DESIGNBathroom Countertops 101: The Top Surface Materials

Explore the pros and cons of 7 popular bathroom countertop materials

Full Story

DECORATING GUIDESMantel Makeover: From Builder's Grade to Live-Edge Wood

See how an all-wrong mantel became a gorgeous fireplace focal point at the hands of an interior designer and her carpenter

Full Story

BATHROOM VANITIESHow to Pick Out a Bathroom Vanity

Choose the right materials, style and size for a vanity that fits your bathroom and works for your needs

Full Story

BATHROOM VANITIESAll the Details on 3 Single-Sink Vanities

Experts reveal what products, materials and paint colors went into and around these three lovely sink cabinets

Full Story

THE ART OF ARCHITECTUREDesign Workshop: Wonderful Material Marriages

See why some materials — concrete and wood, glass and paint, brick and steel — just belong together

Full Story

KITCHEN CABINETSCabinets 101: How to Choose Construction, Materials and Style

Do you want custom, semicustom or stock cabinets? Frameless or framed construction? We review the options

Full Story

KITCHEN COUNTERTOPSKitchen Countertop Materials: 5 More Great Alternatives to Granite

Get a delightfully different look for your kitchen counters with lesser-known materials for a wide range of budgets

Full Story

KITCHEN DESIGNKitchen Counters: Durable, Easy-Clean Soapstone

Give bacteria the boot and say sayonara to stains with this long-lasting material that's a great choice for kitchen and bath countertops

Full Story

KITCHEN DESIGNWonderful Wood Countertops for Kitchen and Bath

Yes, you can enjoy beautifully warm wood counters near water sans worry (almost), with the right type of wood and sealer

Full Story

KITCHEN COUNTERTOPSKitchen Counters: Granite, Still a Go-to Surface Choice

Every slab of this natural stone is one of a kind — but there are things to watch for while you're admiring its unique beauty

Full StoryMore Discussions

Betsey ThompsonOriginal Author

MongoCT

Related Professionals

East Peoria Kitchen & Bathroom Designers · Federal Heights Kitchen & Bathroom Designers · Montebello Kitchen & Bathroom Designers · Woodlawn Kitchen & Bathroom Designers · Andover Kitchen & Bathroom Remodelers · Centerville Kitchen & Bathroom Remodelers · Luling Kitchen & Bathroom Remodelers · New Port Richey East Kitchen & Bathroom Remodelers · Prairie Village Kitchen & Bathroom Remodelers · Mountain Top Kitchen & Bathroom Remodelers · Reston Glass & Shower Door Dealers · Livingston Cabinets & Cabinetry · Tacoma Cabinets & Cabinetry · Boston Window Treatments · Hanover Park Window Treatmentsfotomatt