Insulating a basement

jimbo22s

15 years ago

Related Stories

MATERIALSInsulation Basics: What to Know About Spray Foam

Learn what exactly spray foam is, the pros and cons of using it and why you shouldn’t mess around with installation

Full Story

REMODELING GUIDESCool Your House (and Costs) With the Right Insulation

Insulation offers one of the best paybacks on your investment in your house. Here are some types to discuss with your contractor

Full Story

GREEN BUILDINGInsulation Basics: Heat, R-Value and the Building Envelope

Learn how heat moves through a home and the materials that can stop it, to make sure your insulation is as effective as you think

Full Story

WINDOW TREATMENTSEasy Green: 9 Low-Cost Ways to Insulate Windows and Doors

Block drafts to boost both warmth and energy savings with these inexpensive but effective insulating strategies

Full Story

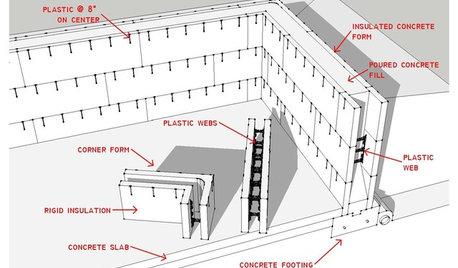

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

MONTHLY HOME CHECKLISTSSeptember Checklist for a Smooth-Running Home

Get ready to get cozy at home with snuggly blankets, well-stocked firewood, added insulation and more

Full Story

ARCHITECTUREHouzz Tour: High Efficiency for a Modern Riverside Cabin

With an insulating green roof, savvy material use and a smart design, this home in the woods wastes not in a beautiful way

Full Story

BASEMENTSBasement of the Week: Fun for All Ages in Connecticut

Crafts, wine, billiards and ... soccer? Yup, this tricked-out family basement has room for all that and more

Full Story

BASEMENTSDesign Workshop: Is It Time to Let Basements Become Extinct?

Costly and often unnecessary, basements may become obsolete — if they aren’t already. Here are responses to every reason to keep them around

Full Story

REMODELING GUIDES10 Tips for Renovating Your Basement

A professional contractor shares her tips on what to consider before you commit to a basement remodel

Full StoryMore Discussions

worthy

jimbo22sOriginal Author

Related Professionals

Goldenrod General Contractors · Perrysburg General Contractors · Towson General Contractors · University Park General Contractors · View Park-Windsor Hills General Contractors · Wallington General Contractors · Birmingham Interior Designers & Decorators · Fountain Hills Interior Designers & Decorators · San Angelo Architects & Building Designers · South Elgin Architects & Building Designers · Wauconda Architects & Building Designers · Lincolnia Flooring Contractors · Monrovia Flooring Contractors · Mukilteo Flooring Contractors · St. Louis Flooring Contractorshomebound

worthy

homebound

jimbo22sOriginal Author

homebound

worthy

jimbo22sOriginal Author

worthy

worthy

jimbo22sOriginal Author

worthy

jimbo22sOriginal Author

jimbo22sOriginal Author

worthy

jimbo22sOriginal Author

worthy

jimbo22sOriginal Author

andrelaplume2

worthy

jimbo22sOriginal Author

worthy

jimbo22sOriginal Author

worthy

dave-maryland

worthy