How to secure wall studs in a basement...?

pete_p_ny

16 years ago

Related Stories

STORAGETap Into Stud Space for More Wall Storage

It’s recess time. Look to hidden wall space to build a nook that’s both practical and appealing to the eye

Full Story

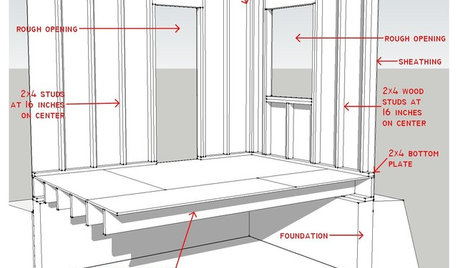

REMODELING GUIDESKnow Your House: Components of Efficient Walls

Learn about studs, rough openings and more in traditional platform-frame exterior walls

Full Story

DIY PROJECTSHow to Create Your Own Semicustom Media Wall

Don’t let the price of a custom built-in stop you. Put one together with ready-made pieces and a little finish help

Full Story

DIY PROJECTSHelpful Hangers: French Cleats Support Projects Big and Small

From cabinets to birdhouses, French cleats hold projects securely in place

Full Story

BASEMENTSDesign Workshop: Is It Time to Let Basements Become Extinct?

Costly and often unnecessary, basements may become obsolete — if they aren’t already. Here are responses to every reason to keep them around

Full Story

REMODELING GUIDESContractor Tips: Finish Your Basement the Right Way

Go underground for the great room your home has been missing. Just make sure you consider these elements of finished basement design

Full Story

STORAGEStorage Walls — the Space-Saving Workhorses of Design

Clear the clutter and even divide a room if you please. With multifunction wall storage, there's nowhere for interior designs to go but up

Full Story

GREAT HOME PROJECTSGet a Grip on Climbing Walls

This fantasy home feature can be surprisingly within reach. Here's what it takes to get some climbing heaven at home

Full Story

KITCHEN DESIGNKitchen of the Week: More Light, Better Layout for a Canadian Victorian

Stripped to the studs, this Toronto kitchen is now brighter and more functional, with a gorgeous wide-open view

Full Story

HOMES AROUND THE WORLDMy Houzz: At Home With Nature Up in the Trees

This homeowner’s creative bungalow on the Australian coast has a bohemian air and a star-studded history

Full StoryMore Discussions

hendricus

Brewbeer

Related Professionals

Brownsville General Contractors · Genesee General Contractors · Great Falls General Contractors · Hamilton Square General Contractors · Lewisburg General Contractors · Mira Loma General Contractors · Aspen Hill Interior Designers & Decorators · Birmingham Interior Designers & Decorators · Cambridge Flooring Contractors · Little Rock Flooring Contractors · Lutz Flooring Contractors · Madison Flooring Contractors · Stevens Point Flooring Contractors · University Park Flooring Contractors · Cocoa Flooring Contractorspete_p_nyOriginal Author

Brewbeer

worthy

pete_p_nyOriginal Author

worthy

matt_r

matt_r

pete_p_nyOriginal Author

worthy

worthy

pete_p_nyOriginal Author

worthy

worthy

al_s

tom_p_pa

worthy

kaysea